Product Description

MC series horizontal multistage centrifugal pumps.

Balance drum, disc type, balancing axial thrust.

Radial bearing and angular-contact bearing gather together to bear the rest force.

Cartridge mechanical seal design.

Standard API610 Flush and cooling.

According to different temperature of the liquid to select right structure, feet support and central bearing.

Smart arrangement of suction and discharge can meet different demands.

Design different hydraulic models to expand BEP area to ensure pump work in high efficiency at different work condition.

Suction type first stage impeller improves anti-cavitations performance.

Easy and convenient maintenance design comforts clients.

CW viewed from drive end.

Product advantage

Compact structure, convenient operation, stable operation, easy maintenance, high efficiency, long service life, and a self-priming function etc

In pipeline no need to install bottom valve, before work only to ensure the pump body reservoir has led to a quantitative liquid.

Simplifies the pipeline system, and improves the working conditions

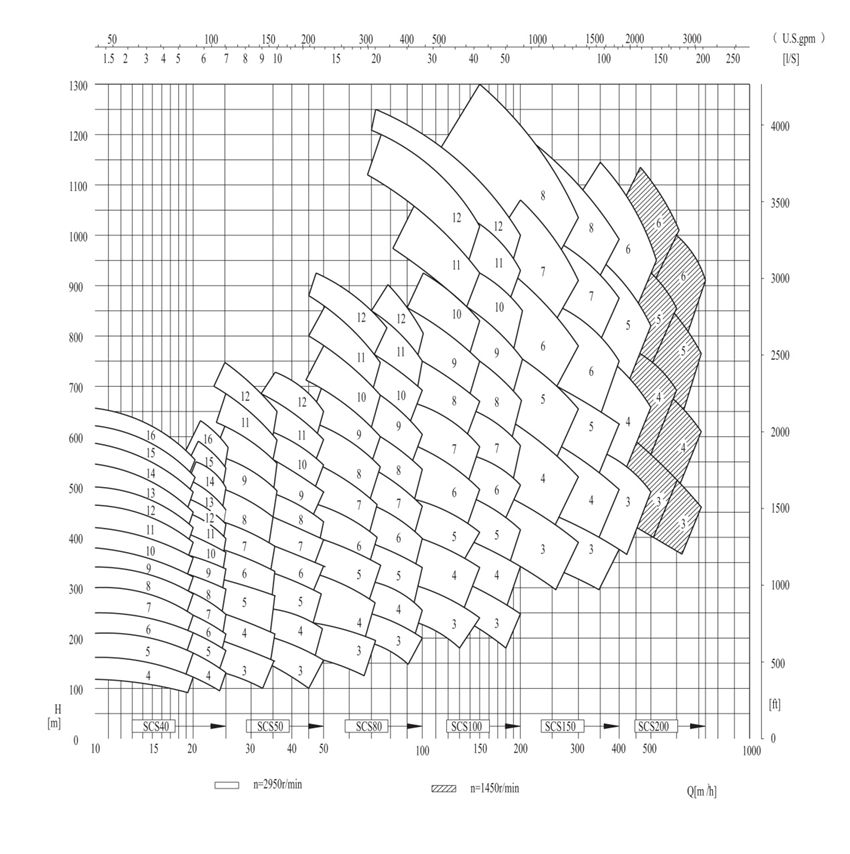

Running Data

Specification DN40-200 outlet dia.

Capacity: up to 600 m /h

Head: up to 1200 m

Pressure: 15.0 MPa

Temperature: -80 ~+180℃

TECHNICAL DATA

Data range

Specification DN40-200 outlet dia.

Capacity: up to 600 m /h

Head: up to 1200 m

Pressure: 15.0 MPa

Temperature: -80 ~+180℃

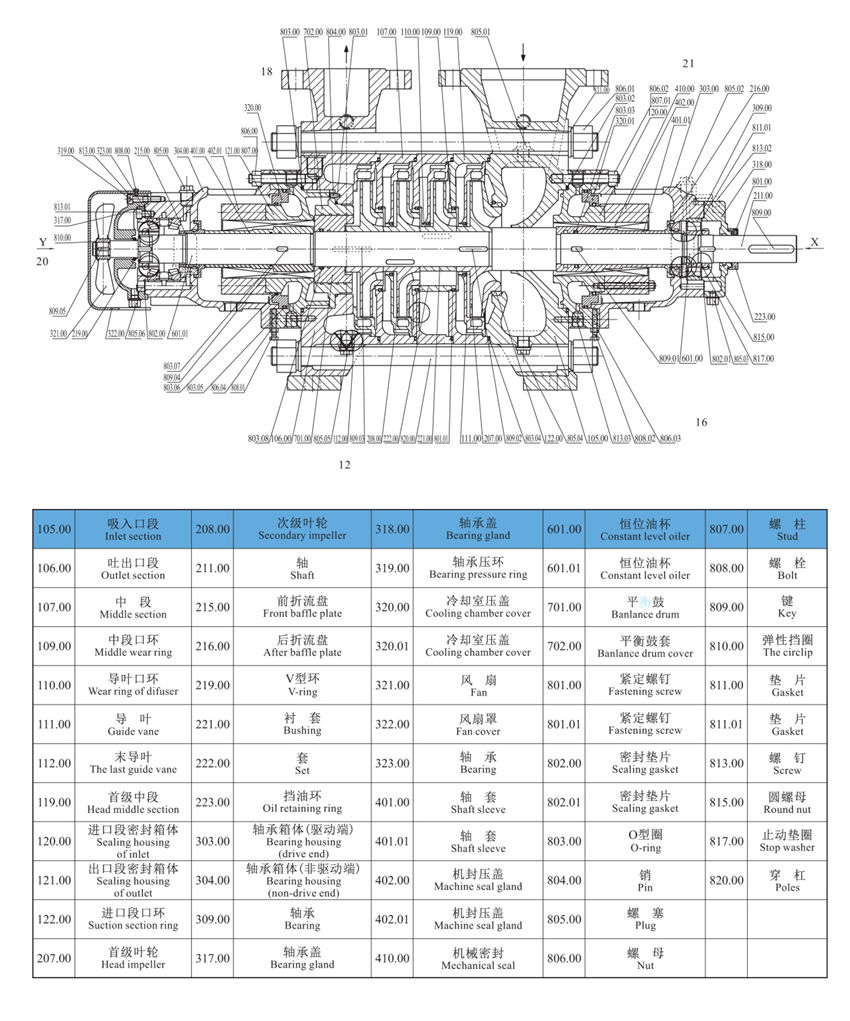

Structure drawing

Characteristics of structure

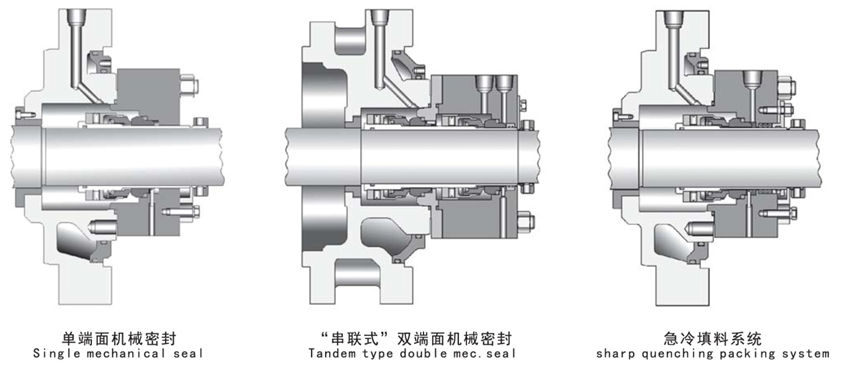

Seals

Cartridge type mechanical seal for drive end and Non-drive end

Cartridge mechanical seal can be equipped With single or tandem double mechanical seal.

For some work condition, it can also be equipped with packing seal system.

For equipping sharp quenching at back of the mechanical seal, sharp quenching packing system should be fit to reduce leakage of sharp quenching fluid.

Housing cooling system can be supplied for various kinds of seal parts

Hydraulic part

Suction type first stage impeller improves anti-cavitation performance

Position of impeller has axial gap, changes of temperature can reduce deformation of shaft.

Different hydraulic models equipment improves HEPdesign and ensures high efficiency for the whole series.

As per requirements, inducer can be equipped to improve anti-cavitation performance.

Suction section and discharge section

Direction of outlet and inlet can be optional.

Different supporting can be selected according todifferent temperature.

Standards of flanges can be decided by users themselves.

Balance devices

Balancing axial force with balance drum or disc, rest

force by thrust bearings.