| Diameter |

25~400mm |

|

|

Flow |

up to 2600m³/h |

|

|

Head |

Up to 300m | |

|

Temperature |

-80~450℃ | |

| Pressure | Up to 5MPa | |

| speed | 1480~3560r/min |

Outline

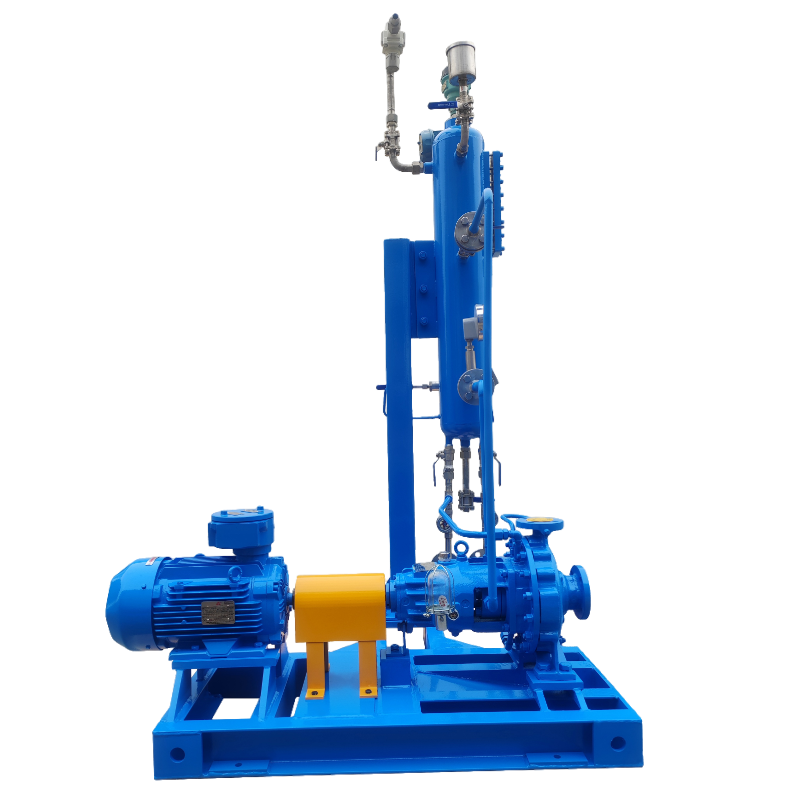

This series of pump sets are designed and manufactured in accordance with the latest API 610 "Centrifugal Pumps for Petroleum, Heavy Chemical and Natural Gas Industries" 10th edition, and their excellent performance and reliable quality provide a solid guarantee for the smooth operation of the project.

Pump advantage

The ZA series pump adopts a single-stage single-suction cantilever structure to achieve an efficient fluid delivery mode of horizontal suction and vertical discharge, and cooperates with the foot support design to ensure the stable operation of the equipment. Its hydraulic performance is based on the international advanced hydraulic model, and is optimized by PUMPCAD aided design system and CFD three-dimensional fluid simulation technology to achieve the industry-leading energy efficiency level.

High efficiency and low consumption: The innovative impeller design and double volute structure (DN80 or above pump type) effectively balance the radial force, reduce vibration and noise, prolong the bearing life, and significantly improve the operating efficiency.

Cavitation control: Through the synergistic effect of the wear rings and the balance hole before and after the impeller, the NPSHr value is optimized to meet the needs of high NPSH working conditions.

Reliable and durable: The all-inclusive shaft design realizes zero contact with the medium, combined with the closed impeller structure, which greatly improves the corrosion resistance and service life of the equipment. The mechanical seal system fully complies with the latest API 682 standard to ensure long-term stable operation.

Strong adaptability: meet the performance of the following operating parameters, and fully adapt to heavy working conditions.

Material solutions:The material of the equipment strictly follows the API 610 specification, and customized matching services are provided. The material grade of the pump body is accurately matched with the pressure level, the key components are made of special alloy steel and corrosion-resistant materials, and the auxiliary sealing system refers to authoritative standards such as the "Industrial Pump Design Manual" to ensure the adaptability of all working conditions.

More detail about our ZA series Horizontal Chemical Process Pump for curve and dimension and data sheet please conatct Tongke.

Application

For transferring clean and little contaminated, lower and high temperature, chemical neutral and corrosive liquid.

√ Refinery, petrol-chemical industry, coal processing and lower temperature engineering

√ Chemical industry, paper-making, pulp, sugar and such like normal processing industry

√ Sea water desalination

√ Auxiliary system of power station

√ Environment protection engineering

√ Ships and offshore engineering

Service Commitment

Our company is equipped with a team of professional engineers to provide full-process technical support and customized solutions. From selection and design, material optimization to on-site commissioning, we can maximize the life cycle value of equipment in an all-round way, and help customers achieve safe and efficient production goals.