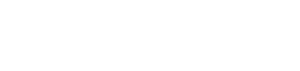

Self Priming Dewatering Pump Set

With Dry Running Ability.

Why Choose Us?

Professional Pump Manufacturers Since 2001 With ISO9001-2015/ISO 45001/ISO14001

Specialized Production Manufacturer For Self-Priming Pump

Focus On Technological Innovation, Over Industry Leading Level

We Have Good Experience At Domestic And Oversea Market

Years Of International Service Standards, Engineer One-To-One Service

Provide Reliable Product Quality And Perfect After-Sales Service

Three Types Of Products Are Available To Meet Your Various Needs!

Model No:TWP

Description:

TWP series Movable Diesel Engine Self-priming Well point Water Pumps for emergency are joint designed by DRAKOS PUMP of Singapore and REEOFLO company of Germany . This series of pump can transport all kinds of clean, neutral and corrosive medium containing particles. Solve a lot of traditional self-priming pump faults. This kind of self-priming pump unique dry running structure will be automatic startup and restart without liquid for first start, The suction head can be more than 9 m; Excellent hydraulic design and unique structure keep the high efficiency more than 75%. And different structure installation for optional.

Options Include:

● 316 or CD4MCu stainless steel pump-end construction for high and low pH applications.

● Highway trailer or skid mount, both incorporating integral overnight running fuel tanks.

● Sound attenuated enclosures.

Customized Movable Diesel Engine Silenced Type Specialized Self Priming Pump

Model No:Base On SPDW Series

Description:

The Silenced type pump set is based on SPDW. Designed for mobile pump sets, this semi-shield has been innovatively adapted to the specific needs of the customer while retaining many of the advantages of the original SPDW model.

This design is designed to achieve two core objectives: one is to significantly reduce diesel engine noise emissions, and the other is to effectively control costs and maximize economic benefits.

Highlights

● Strengthening of sealing.

● Semi-enclosed design.

● Efficient noise reduction.

● Rainproof and dust-proof, beautiful and fashionable.

Silenced Type Movable Specialized Self Priming Diesel Engine Pump

Model No:Base On SPDW Series

Description:

The Silenced type pump set is based on SPDW with a silent passport. It retains the design features and advantages of SPDW.

This series of pump can transport all kinds of clean, neutral and corrosive medium containing particles. Solve a lot of traditional self-priming pump faults. This kind of self-priming pump unique dry running structure will be automatic startup and restart without liquid for first start. The suction head can be more than 9 m; Excellent hydraulic design and unique structure keep the high efficiency more than 75%. And different structure installation for optional.

Highlights

● Soundproof combustion inter-layer.

● Heat dissipation and ventilation design.

● Super Efficient noise reduction.

● Rainproof and dust-proof, beautiful and fashionable.

Specification/Performance Data

|

SPDW-100 |

SPDW-150 |

SPDW-200 |

SPDW-250 |

SPDW-300 |

SPDW-400 |

SPDW-500 |

SPDW-600 |

|

|

Engine Power /Speed-KW/rpm |

24/1800(1500) |

36/1800(1500) |

60/1800(1500) |

110/1800(1500) |

163/1800(1500) |

330/1800(1500) |

400/1500(1800) |

680/1500/1800 |

|

Dimensions |

194 x 145 x 15 |

220 x 150 x 164 |

243 x 157 x 18 |

263x160x170 |

310X175X180 |

355X180X190 |

470X180X190 |

590X180X220 |

|

Solids Handling - mm |

44 |

48 |

52 |

58 |

65 |

75 |

80 |

85 |

|

Max Head/Max Flow - m/M3/h |

45/180 |

44/400 |

65/600 |

56/900 |

54/1200 |

76/2500 |

80/3200 |

80/4500 |

Structure Characteristic

High self-priming pressure

Synchronous self priming ,according to the local atmospheric pressure difference the highest suction head can be 9.5m, far higher than the traditional self suction pump.

Quick start and restart

Using a unique dry running structure, the first time to start the pump is also no need to have a liquid, can be directly started to work, reduce the field operation.

Ultra high efficiency

With excellent hydraulic model and unique design structure, the pump efficiency high up to 80%, compared with the normal self priming pump ,the efficiency will be higher than 25%. Save the running costs.

The use of semi open impeller design

Pumping with various fibers and solid particles of media, the largest by 50mm solid particles flange according to the user's specific requirements, The wet parts can be used cast iron ,cast steel and all kind of stainless steel or Duplex SS material to transfer the corrosive type liquid. The seal can be choose the M/S or gland packing.

Video Show

TKFLO Pump Advantages

● Suction head reach to 9.5 m. Vertical suction lift in under 1 minute even on "snore".

● Quick start and restart. No need feeding water before start, first start is the same way. Reduce the site work.

● Long use time-Heavy duty internal pump bearings.

● Pass the solid particles up to 75 mm. Sensible choice under various working condition. Due to pass the large diameter solid particles, so this SPH pumps are suitable for deep.

● High capacity air handing can be qualified for Well point dewatering engineering.

● Move the work site at any time for we have double wheels and single wheel design.

● By controlled floating gas water separation system to ensure that the suction-extended priming efficiency- rapid on-site change in minutes ( mechanical seal option.)

● Built-in fuel tank for longer running ( Additional fuel tank available optional ).

● Auto mastic startup control panel.

● Super size inspection hole cover to facility clean.

● Dry running ability.

● Air separator tank easy for service, stainless steel material is optional.

● Long running time with minimal service intervention.

● Flange standard: GB, HG, DIN, ANSI standard, according to your requirements.

● A variety of material to choose:

Cast iron/ stainless steel/ steel/ Ductile iron/ Duplex stainless steel.

Shaft seal: mechanical seal / packing seal

* subject to geology, fluid density, losses

Custom Solution Showcase —— Bridging Drainage Projects

Pump Model:SPH

SPH series self priming pumps are joint designed by Tongke Flow and DP pumps of Singapore. The new design is different from the traditional self priming pumps, the pump can be dry running at any time, it can fast automatic start up and restart. First start without feeding liquid to the pump casing, the suction head will be running on high efficiency. It is over than 20% compare to the normal self priming pumps.

Payment & Shipping Terms:

Minimum Order Quantity: 1 set

Price: Negotiation

Packaging Details: Export Packing

Delivery Time: 45 working days

Payment Item: T/T or L/C

Multi-purpose Solution :

● Standard sump pumping

● Slurry & semi solid material

● Well pointing - high vacuum pump capacity

● Dry running applications

● 24 hour reliability

● Designed for high ambient environments

Market Sectors:

● Building & Construction - well pointing and sump pumping

● Water & Waste - over pumping and systems bypass

● Quarries & Mines - sump pumping

● Emergency Water Control - sump pumping

● Docks, Ports & Harbors - sump pumping and stabilization of loads

TKFLO Movable Emergency Flood Control Diesel Engine Self-Priming Water well point dewatering Pump,After more than ten years of market test, continuous design and innovation, widely praised in overseas markets.

Partial sample engineering for refer. More please contact TKFLO sales team, they will 24 hours online for you.

TKFLO Company Profile

Centered around technological innovation and pursuing superior quality To be a world-class provider of fluid transfer solutions.

Shanghai Tongke Flow Technology Co., Ltd is a technology-based enterprise integrating technological innovation and environmental protection concepts. Since its establishment in 2001, it has always been committed to the cutting-edge research and development and production of fluid conveying products and intelligent fluid equipment, and has been deeply engaged in the field of enterprise energy-saving transformation services. Adhering to the original intention of green development, the company continues to promote the energy-saving and environmental protection upgrading of cutting-edge technology products, and continues to lead the industry innovation trend.

Tongke Flow Technology, as the supplier of a full range of Fluid equipment solutions in the industry, is not only specialized in manufacturing comprehensive fluid equipment products including pumps, motors and efficient control systems, but also adept in customizing high-quality and feasible technical solutions according to client needs to help the efficient operation of enterprise projects and achieve a win-win situation of economic and environmental benefits.

TKFLO Brand Strength

High Qualified Technical Engineer Team

The company has strong technical support, and has created an interdisciplinary and high-quality technical team relying on the rich resources of Shanghai Tongji Nanhui Science and Technology Park, including doctoral supervisors, professors, senior engineers and many senior engineers. They provide inexhaustible driving force for the company's technological innovation and product upgrades by virtue of their profound professional knowledge and rich practical experience.

Excellent Manufacturing Capabilities

In terms of production, Tongke Flow Technology shows excellent manufacturing capabilities. Since 2010, the company has established modern production bases in Shanghai, Jiangsu, Dalian and other places, with a total area of 25,000 square meters, production facilities area of more than 15,000 square meters, equipped with 5 efficient production lines, fully covering the pump, motor, control system and other full range of fluid equipment products, to ensure high quality and high efficiency products.

Excellent Product Manufacture

Tongke Flow Technology, excellence in manufacturing. We strive for perfection in every aspect of production and offer comprehensive testing and inspection services to ensure product quality. Customer satisfaction is the gold standard by which we measure our product quality and is the driving force behind our continuous improvement.

At the same time Tongke improved the technology of more than ten traditional pumps such as vertical turbine, submersible pump, end-suction pump and multistage centrifugal pump, significantly enhancing the overall technological level of traditional product lines.

Focus On Customer Needs And Service

In terms of service, Tongke Flow Technology covers major cities all over the county with its business network, and its clients are involved in many fields. The company has successfully carried out technological transformation for nearly 20 large state-owned enterprises and joint-stock enterprises in the Yangtze River Delta, Pearl River Delta, Central China and North China. Our solutions have not only brought significant economic benefits, but also won widespread social praise, especially in the chemical, chemical fiber, steel, fertilizer, pharmaceutical, thermal and other industries.

Tongke Flow Technology adheres to self-development, with its products being exported to more than 50 countries, and constantly expands its shares in the international market and enhance brand influence. We are deeply aware that only by constantly pursuing excellence can we remain invincible in the fierce market competition.

Everlasting Self Innovation

Tongke Flow Technology adheres to self-development, with its products being exported to more than 50 countries, and constantly expands its shares in the international market and enhance brand influence. We are deeply aware that only by constantly pursuing excellence can we remain invincible in the fierce market competition.

Looking at the way forward, Tongke Flow Technology will continue to adhere to the core values of professionalism, innovation, and service, and provide clients with high-quality and modern fluid technology solutions by manufacturing and product teams under the leadership of the professional leadership team to create a better future.

Enterprise Qualification

Since its inception, our company has steadfastly adhered to the core purpose of "focusing on technological innovation, striving for quality enhancement, and committing to providing professional services to solve customer issues." We have continually refined our skills and strengthened our brand image. Over the years, we have not only received numerous authoritative certifications and accolades but have also successfully passed the stringent certifications of ISO 9001-2015 International Quality Management System, ISO 14001 Environmental Management System, and ISO 45001. Occupational Health and Safety Management System. We consistently adhere to international standards, ensuring the stability and reliability of our product and service quality, winning widespread acclaim and trust in the market.

Our Exhibition And Customer Visits

Now TKFLO products exporting to more than 50 countries across the face of the globe well received by our customers.

Putting heart in to technology inactivation in our pursuit of quality improvement,

To provide first-class fluid transport solutions all over the world.

FAQS

A dewatering pump is a specialized pump designed to remove water or other fluids from a specific area. They are essential in various applications, including construction sites (removing water from excavations), mines (controlling groundwater inflow), and flood control (draining affected areas). Dewatering pumps can handle clear water, as well as water containing solids like sand, silt, or debris, depending on the specific pump type.

Several types of dewatering pumps exist, each suited to different applications. Submersible pumps operate while fully submerged in the fluid, while surface pumps sit outside the water source and draw water through a suction hose. Trash pumps are designed to handle water with large solids and debris, while sludge pumps are built for viscous fluids and slurries. Centrifugal pumps are a common type of dewatering pump that uses a rotating impeller to move water.

Selecting the correct dewatering pump depends on several factors. These include the volume of water to be removed, the distance the water needs to be moved (head pressure), the type of fluid (clear water vs. solids-laden water), the size of any solids present, and the power source available. Consulting with a pump specialist or referring to manufacturer specifications is highly recommended.

"Head" refers to the total vertical distance a pump can lift water, including any friction losses in the piping. It's a crucial factor in pump selection. A pump with insufficient head won't be able to move the water to the desired location. Total Dynamic Head (TDH) is the sum of the static head (vertical lift) and friction head (losses due to pipe friction).

Regular maintenance is vital for ensuring the longevity and performance of a dewatering pump. This typically includes inspecting the pump for wear and tear, cleaning or replacing filters, checking hoses and connections for leaks, lubricating moving parts, and ensuring the pump is properly grounded. Refer to the manufacturer's manual for specific maintenance instructions.

A self-priming pump is a centrifugal pump designed to lift water from a level below the pump's suction inlet without requiring manual priming. They achieve this through a unique pump casing design that retains a certain amount of liquid even after the pump is shut off. This retained liquid helps create a vacuum when the pump restarts, allowing it to draw water up the suction line.

The primary advantage of a self-priming pump is its ability to operate without the need for manual priming, saving time and effort. This makes them ideal for applications where access to the pump suction is limited or inconvenient. They are also useful in situations where the pump may need to start and stop frequently.

Self-priming pumps find applications in various settings, including irrigation, dewatering, sewage transfer, and general water transfer. They are frequently used in agricultural settings, construction sites, and municipal water system

Self-priming pumps have limitations regarding suction lift. They can only lift water up to a certain height, typically not exceeding 25 feet. They are also not suitable for highly viscous fluids or fluids containing large solids. The priming capability can also be lost if the pump casing loses its retained liquid due to a leak or other issue.

Maintaining a self-priming pump is similar to maintaining other centrifugal pumps. Regular inspections for wear and tear, checking for leaks, lubricating moving parts, and ensuring proper alignment are essential. It's also important to periodically check the level of retained liquid in the pump casing and ensure the suction line is free from obstructions. Consult the manufacturer's manual for specific maintenance recommendations.

sales@tkflow.com

sales@tkflow.com