|

Capacity |

1800-13860m³/h |  |

|

Head |

2~12m |

|

|

Working Temperature |

-20~60ºC |

Material of Floating Pump

Bowl: Cast iron, Stainless steel

Shaft: Stainless steel

Impeller: Cast iron, Bronze or Stainless steel

Discharge head: Cast iron or carbon steel

Pump advantage

Portability: They can be easily moved to another location of operation without requiring civil engineering.

Economical: They avoid the expensive civil construction and operational disruption required to install traditional stations.

Aspirate clear water: Prevents sediment from being sucked up from the bottom of the reservoir by sucking the water closest to the free surface.

Efficiency: The entire system is optimized to operate at the highest overall efficiency.

Continuous duty: A variety of materials are available for the water pump and system to meet the requirements of continuous use in corrosion-resistant, salt-resistant and other environments.

High Quality: As with the manufacture of the pump, the same strict quality controls apply to all components of the floating system.

More detail about our Floating Pump for curve and dimension and data sheet please conatct Tongke.

※ More detail about our Floating Pump for curve and dimension and data sheet please contact Tongke.

Outline

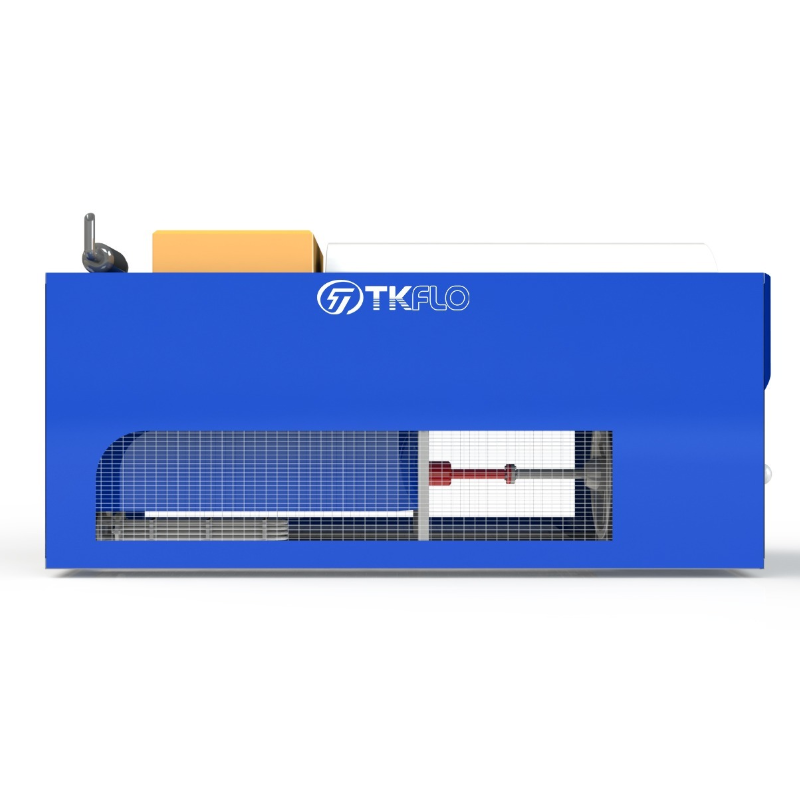

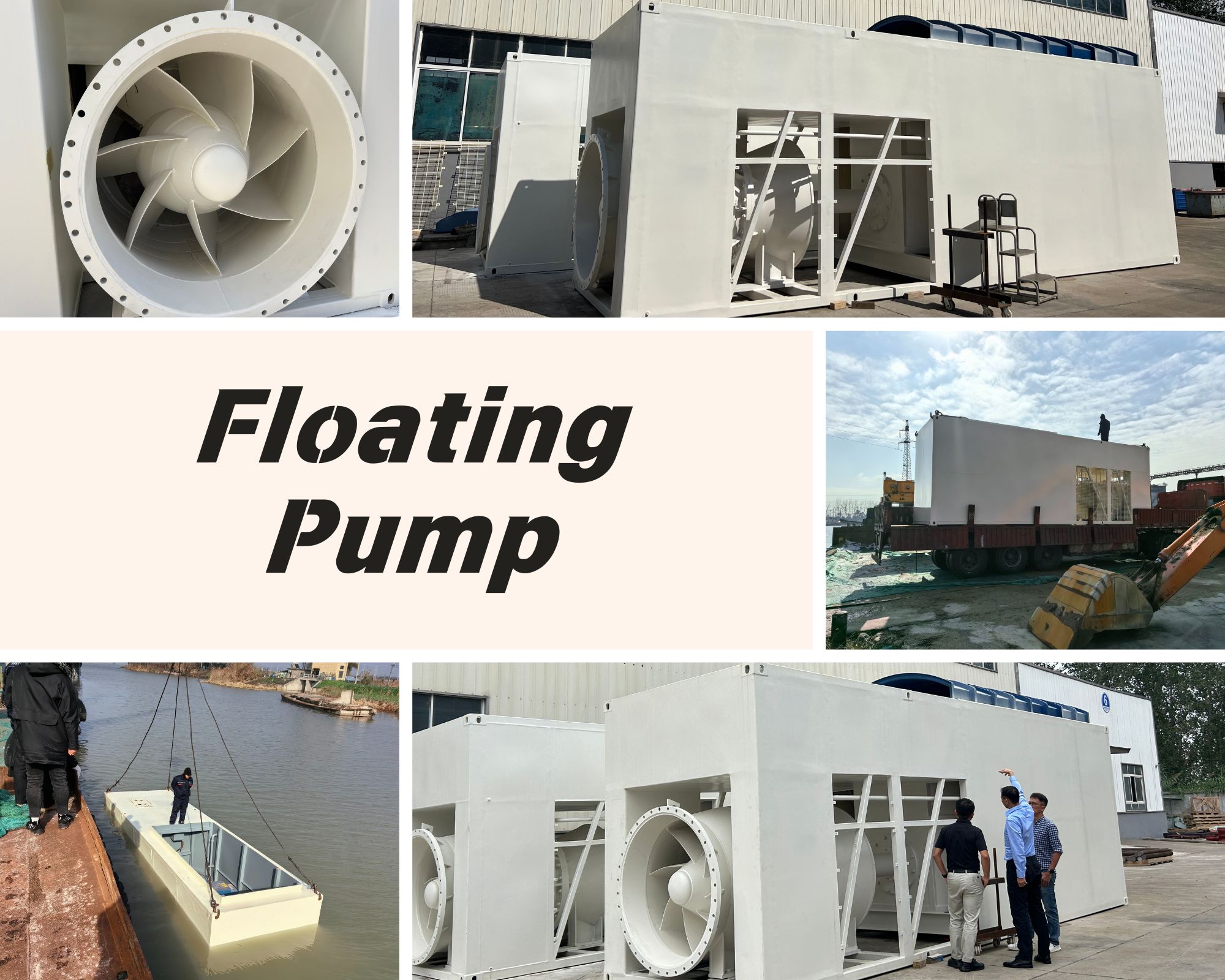

TKFLO floating pump systems are integral pumping solutions that operate in reservoirs, lagoons, and rivers. They are equipped with submersible turbine pump, hydraulic, electrical, and electronic systems to operate as high performance and high reliability pumping stations.

TKFLO pumps designs and builds big floating pump, it suitable for most pump designs. Our design process begins with the customers' requirements. From there, our engineers design a whole plan to meet your requirements taking in to consideration weather conditions, equipment down thrust, fluid pH, environment and personnel.

Custom designed floating pump can provide you with a floating pumping system for application over a large body over water. Our team of engineers will work closely with you to create a floating pump system to your specifications, and we pride ourselves on meeting the requirements of most applications.

Feature

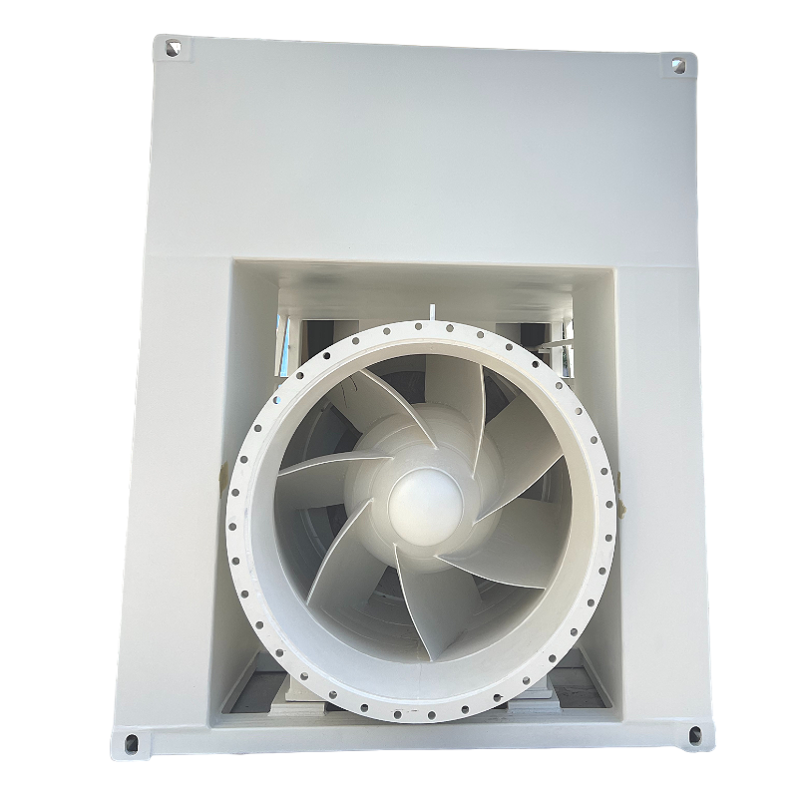

1.Axial floating pump with standard rotation for high efficiency at low heads.

2."Ready to run"

3.Versatile

4.Low maintenance costs

5.Excellent cost-benefit ratio Naval steel pump body

6.Compact hull design for easy transportation and handling.

7.The geometry of the hull has smooth curves to improve the water entry profile and receive an optimum hydraulic performance in multiple installation conditions.

8.Reliable design, widely used propulsion drive line with marine transmission

9.Performance: Maximum TDH up to 12M The Intake is protected with a metal grid Stainless steel 304 wear-ring, protecting the area influenced by the impeller Stainless Steel 304 profiled Cast blades for the impeller. The impeller is anesthetized through heat treatment.

It's design and construction allows the equipment to save energy and to improve efficiencies. It´s a resistant equipment to adverse situations that may be present in the different water intake, for example: strong watercourses, fluctuating tides, waste, etc.

Designed for continuous operation with the capacity to handle large water volumes

• Complete integrated unit

• Ideal structural design and light weight

• Long lasting high resistance construction materials

• Civil works significantly reduced by design, doesn't require to build a pumping station for functioning quick installation and start-up. Flexibility to conditions of fluctuating levels due to natural effects or climate changes.

• Alternative pumping station solution in areas with highly unstable soils

• Easy relocation, they can operate in any other place require with similar hydraulic conditions.

• Floating Pumps don´t have problems of alignment, stability, anchoring or load manage.

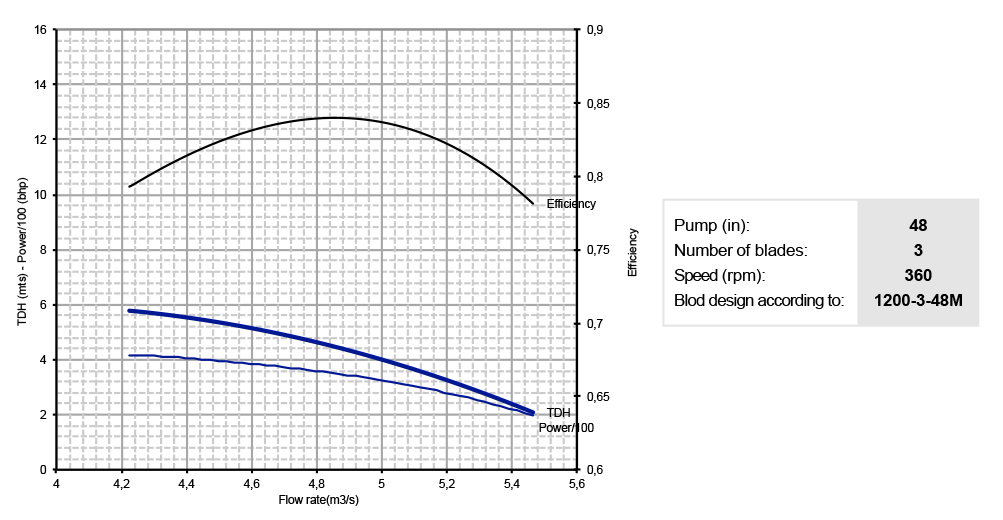

TECHNICAL DATA

|

Model |

BF V3 - 48MS |

|

|

Impeller Diameter (in) |

48 |

|

|

Engine Type |

Diesel |

|

|

Maximum Flow (m3/s) |

5.7 |

|

|

Maximum Dynamic Head TDH (m) |

5.81 |

|

|

Maximum Power Demand (Hp) |

419 |

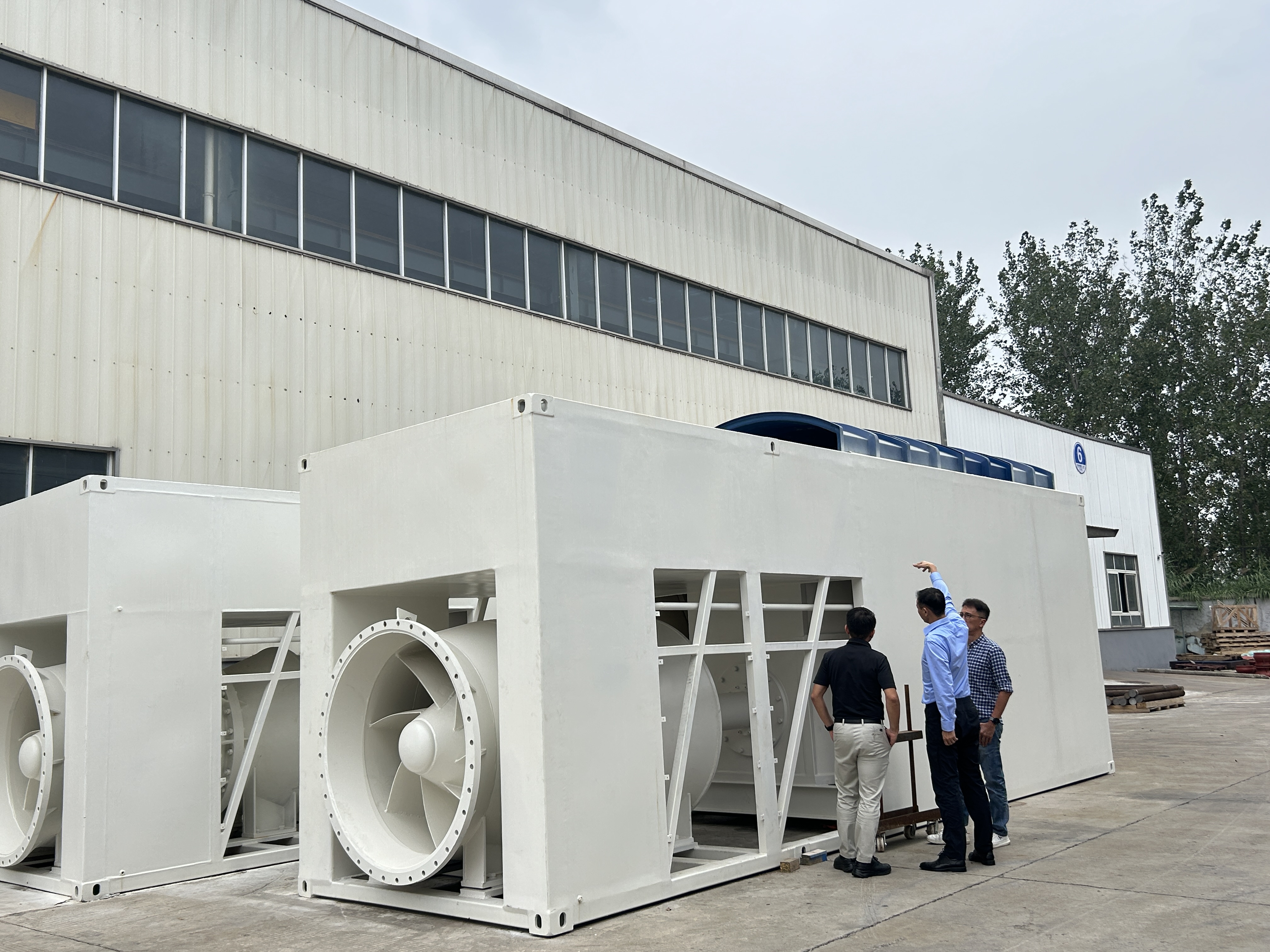

Detail Photos

APPLICATION

- 1.Water supply

- 2.Mining;

- 3.Flood control and drainage;

- 4.Pumping water from the river for drinking water systems;

- 5.Pumping water from the river for irrigation systems in agro-industry.

- 6.Simple installation and infrastructure is needed;

- 7.Quick installation and startup;

- 8.Simply move equipment to different pump zones;

- 9.The highest water quality can be achieved.,due to surface suction;

- 10.Constructed of lightweight high-resistance materials, low cost and simple maintenance;

A variety of materials are available for the water pump and system to meet the requirements of continuous use in corrosion-resistant, salt-resistant and other environments.

Sample project

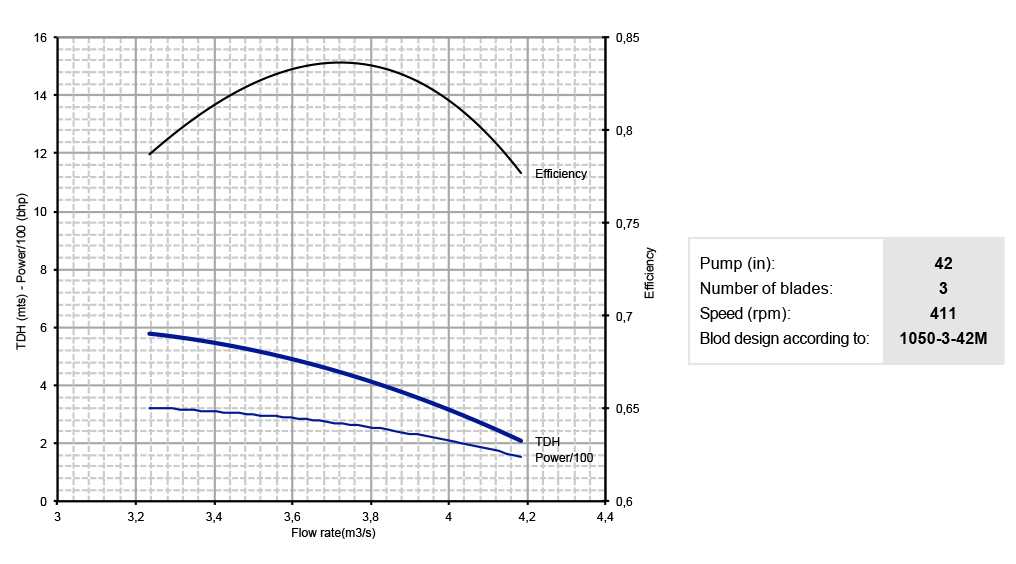

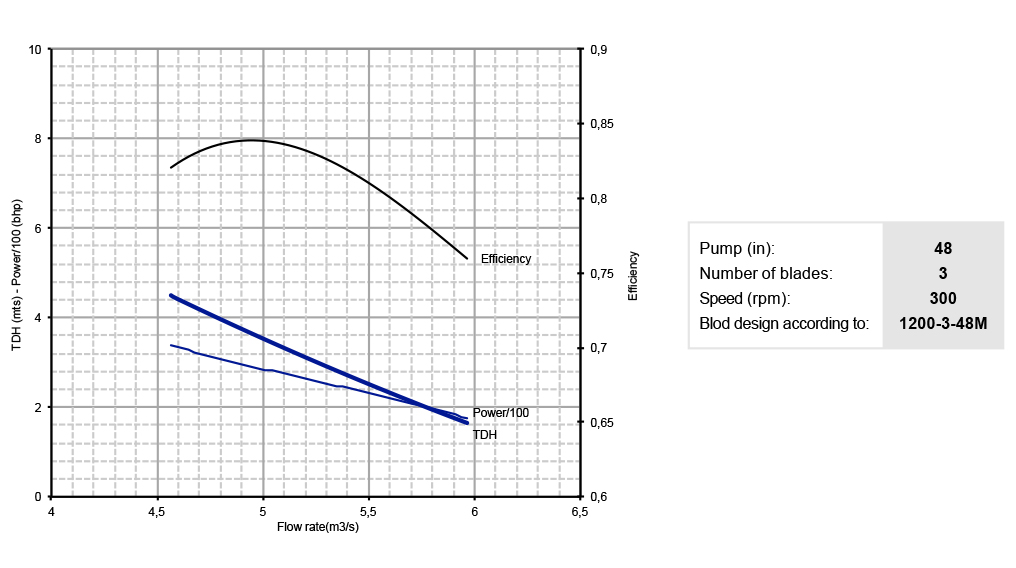

CURVE