A diesel multistage pump offers the premier solution for high-pressure or long-distance water transfer in remote, off-grid locations. This specialized water Drainage Pump uses multiple impellers to build pressure progressively. It overcomes significant elevation and distance challenges that single-stage pumps cannot handle. The increasing demand for powerful water management solutions is clear, with the global market showing significant growth.

| Metric | Value |

|---|---|

| Market Size (2024) | USD 6.8 billion |

| Projected Market Size (2033) | USD 11.5 billion |

| CAGR (2025-2033) | 6.7% |

This makes the multistage pump a definitive tool for demanding environments.

Why Choose a Diesel Multistage Pump?

A diesel multistage pump is an indispensable asset for serious water management projects. Its design delivers a unique combination of power, pressure, and portability that other systems cannot match in remote environments. Operators choose this equipment for three primary reasons: its standalone power, its ability to move water over extreme heights and distances, and its capacity for high-volume drainage.

Unmatched Off–Grid Power

Diesel engines provide robust, self-contained power. This makes them the ideal choice for locations far from a reliable electrical grid. Agricultural fields, remote mining sites, and isolated construction zones often lack the infrastructure to support large electric motors. A diesel pump operates independently, requiring only fuel to run at full capacity.

Note: This autonomy ensures that critical dewatering or water transfer operations can continue without interruption, regardless of grid stability or location. It places complete operational control directly in the hands of the user.

Overcoming High Head and Distance

The term “high head” refers to the total resistance a pump must overcome, including vertical lift and friction loss from long pipes. A multistage pump excels here. It uses a series of impellers, with each stage boosting the water pressure higher than the last. This progressive pressurization allows the pump to move water to incredible elevations. Certain models demonstrate this power, with maximum total heads reaching 557 feet. Some specialized vertical pumps can even achieve heads of up to 978 meters, conquering challenges that are impossible for single-stage pumps.

Efficient High-Volume Drainage

These pumps combine high pressure with substantial flow rates, making them perfect for large-scale drainage. A mining operation in Peru provides an excellent case study. The company needed to dewater a deep open-pit mine where electric pumps were unsafe and impractical. By implementing surface-mounted diesel pumps, they effectively removed water from depths of 1,200 feet. This solution eliminated dangerous electrical cables in the mine and allowed for remote monitoring, which improved safety and operational efficiency.

How to Select the Right Pump in 2025

Selecting the correct diesel pump is a technical process that ensures optimal performance, efficiency, and equipment longevity. A mismatched pump can lead to inadequate water flow, premature wear, and wasted fuel. The selection process hinges on three critical steps: calculating the system’s resistance, determining the necessary flow rate, and matching these requirements to the right pump model using its performance curve.

Step 1: Calculate Total Dynamic Head

Total Dynamic Head (TDH) is the total equivalent height that fluid must be pumped, considering all sources of resistance in the system. It is the most critical factor in pump selection. An accurate TDH calculation prevents under-sizing or over-sizing the pump. The standard formula is straightforward:

TDH = Static Head + Friction Losses

To calculate TDH, an operator must first gather key data points about the system.

| Input Parameter | Description |

|---|---|

| Static Head | The total vertical distance from the water source’s surface to the final discharge point. |

| Pipe Length & Diameter | The total length and internal diameter of all pipes in the system. |

| Pipe Material | The material of the pipe (e.g., PVC, steel), which has a specific roughness coefficient. |

| Fittings and Valves | The number and type of elbows, tees, and valves, which add to friction. |

| Required Flow Rate | The volume of water to be moved, measured in Gallons Per Minute (GPM) or m³/h. |

Static Head is the vertical lift required. It is the sum of the suction lift (from the water source to the pump) and the discharge head (from the pump to the outlet).

Friction Losses represent the energy lost as water moves through pipes and fittings. Longer pipes, smaller pipe diameters, and a higher number of bends all increase friction. For example, moving 15 GPM through 200 feet of 0.5-inch pipe creates a massive 610 PSI of resistance. Using a 1.5-inch pipe for the same task drops that resistance to just 2.2 PSI. This demonstrates how a wider pipe diameter significantly reduces friction and improves system efficiency.

While manual calculations are possible, several online tools can simplify the process. Resources like the Hung Pump Group Taiwan online calculator or the University of Wisconsin TDH calculator help users determine TDH by inputting their system parameters.

Step 2: Determine Required Flow Rate

The required flow rate is the volume of water a user needs to move in a given amount of time, typically measured in Gallons Per Minute (GPM). This requirement is entirely dependent on the application. A pump sized for a small farm will be insufficient for a large-scale dewatering project.

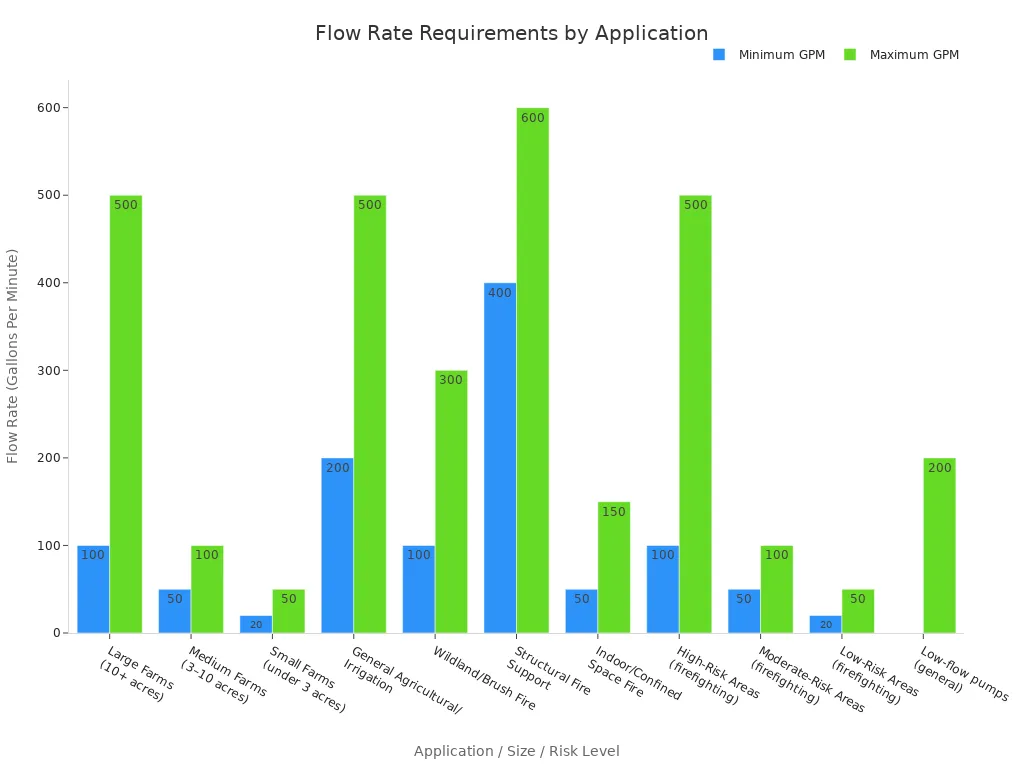

Operators should define their needs based on the specific task. The chart below illustrates the wide range of flow rates for common off-grid applications.

Here are some typical flow rate requirements:

·Agricultural Irrigation: A small farm under 3 acres may only need 20–50 GPM, while large commercial farms often require 100 GPM or more.

·Construction Dewatering: General dewatering tasks can start with low-flow pumps under 200 GPM, but larger sites may need significantly more capacity.

·Remote Firefighting: A wildland fire might require 100–300 GPM, whereas supporting a structural fire could demand 400–600 GPM.

Choosing the right flow rate is a balance. An oversized pump wastes fuel, while an undersized pump fails to complete the job in a timely manner. The powerful Tongke diesel engine vertical turbine multistage pump, for instance, offers a massive capacity range from 20 to 5000 m³/h (approx. 88 to 22,000 GPM), making it adaptable to nearly any large-scale drainage or transfer task.

Step 3: Read a Pump Performance Curve

A pump performance curve is a graph that shows a pump’s capabilities at a given operating speed. It is the final and most important tool for matching a pump to a system’s needs. The curve plots the flow rate (GPM) on the horizontal axis against the total dynamic head (TDH) on the vertical axis.

To use the curve:

1.Locate your required flow rate on the horizontal (X) axis.

2.Locate your calculated TDH on the vertical (Y) axis.

3.Find the intersection point of these two values on the graph.

This intersection point is your system’s duty point. For a pump to be suitable, this duty point must fall on or very close to the pump’s main performance curve line.

Pro Tip: Look for the Best Efficiency Point (BEP). The BEP is the point on the curve where the multistage pump operates with the highest efficiency. Operating at or near the BEP provides significant financial and mechanical benefits, including lower fuel consumption, minimal vibration, and reduced wear on components. This extends the pump’s operational life and ensures the most cost-effective performance.

Step 4: Consider Modern Engine and Materials

Beyond head and flow calculations, the physical construction of the pump and its engine are critical for long-term success. In 2025, advancements in engine technology and material science directly impact a pump’s efficiency, lifespan, and environmental compliance. A smart buyer evaluates both the power source and the pump’s durability.

Modern Engine Technology: Efficiency Meets Compliance

The diesel engine is the heart of the pump. Modern engines are not just powerful; they are intelligent and clean. The most significant development is the widespread adoption of EPA Tier 4 Final emissions standards. These regulations mandate a drastic reduction in harmful pollutants. Compared to pre-2008 levels, Tier 4 engines cut particulate matter (PM) and nitrogen oxides (NOx) by up to 99%.

This is achieved through a suite of advanced, computer-controlled systems:

·Selective Catalytic Reduction (SCR): This system is a game-changer for emissions. It injects Diesel Exhaust Fluid (DEF) into the exhaust stream. A chemical reaction then converts up to 90% of harmful NOx into harmless nitrogen and water.

·Diesel Particulate Filter (DPF): The DPF acts like a trap, capturing soot and other particulate matter from the exhaust.

·Exhaust Gas Recirculation (EGR): This process redirects a small portion of exhaust gas back into the engine. This lowers combustion temperatures and reduces the initial formation of NOx.

·Electronic Control Units (ECU): The ECU is the engine’s brain. It constantly monitors operating conditions and adjusts the fuel-to-air ratio for optimal performance and minimal emissions.

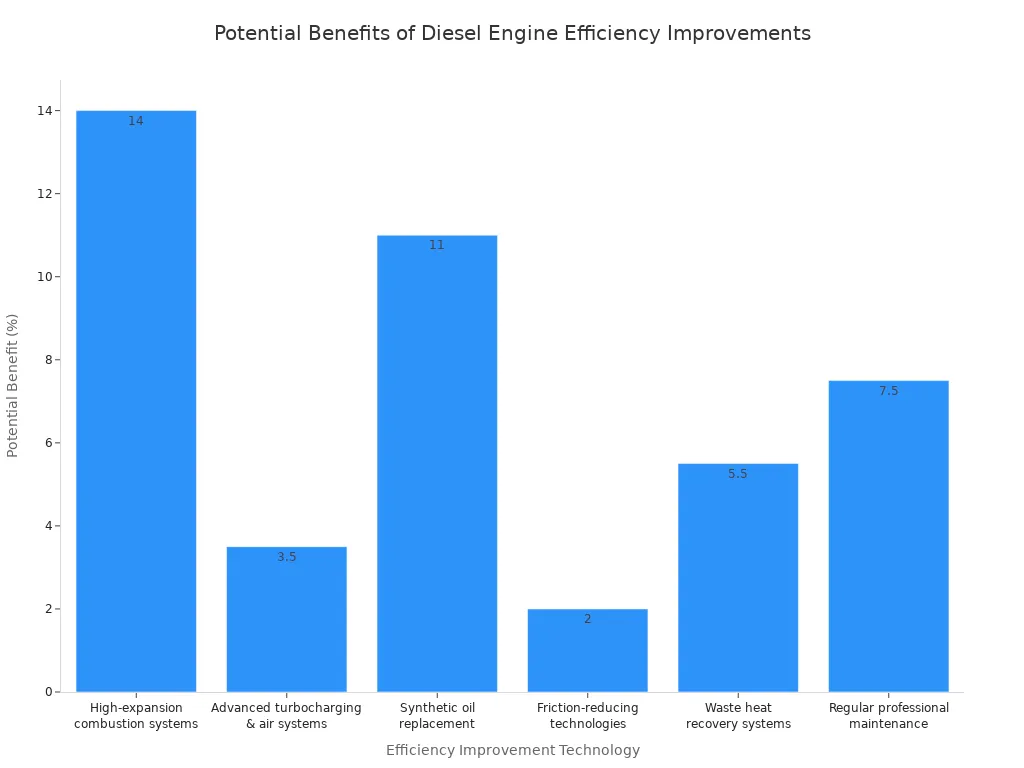

The Financial Benefit: These emission control systems do more than protect the environment. They improve fuel economy. Tier 4 engines convert fuel to energy more efficiently, leading to significant long-term cost savings. In April 2024, Weichai Power even unveiled a diesel engine with a record-breaking 53.09% thermal efficiency, promising a 14% fuel economy improvement over typical engines.

The following chart illustrates how various technological improvements contribute to greater fuel efficiency.

Advanced Pump Materials: Built for Durability

The engine provides the power, but the pump’s materials determine its resilience. A well-built multistage pump withstands harsh conditions, resists wear, and requires less maintenance. When selecting a pump, operators should inspect the materials used for key components.

High-quality pumps, like the Tongke vertical turbine series, offer superior material options tailored to specific applications.

| Component | Standard Material | Premium/Specialized Options | Purpose |

|---|---|---|---|

| Impellers | Cast Iron | Bronze, Stainless Steel | Bronze offers excellent corrosion resistance. Stainless steel provides maximum durability and wear resistance. |

| Shaft | Carbon Steel | Stainless Steel | Stainless steel prevents rust and ensures long-term structural integrity under high torque. |

| Bowls | Cast Iron | Stainless Steel | Stainless steel is ideal for pumping corrosive or abrasive liquids. |

| Bearings | Standard Brand | Thordon Bearings | Thordon bearings are specifically designed for seawater applications, offering superior performance in saline environments. |

Application-Specific Design: For pumping liquids with abrasive solids like sand or scrap iron, look for models with features like muff armor tubing and abrasive-resistant impellers. These enhancements protect the pump’s internal components from premature wear, ensuring a longer operational life and a better return on investment.

Choosing a pump made with robust, corrosion-resistant materials ensures it will perform reliably for years, even in the most demanding off-grid environments.

Practical Guide to Installation and Operation

Proper installation and operation are fundamental to maximizing a pump’s performance and lifespan. A methodical approach to setup prevents equipment damage and ensures safe, efficient water transfer from day one. Operators should focus on creating a stable foundation, selecting the correct piping, and following a strict startup procedure.

Site Prep and Pump Placement

A solid, level foundation is non-negotiable for heavy-duty diesel pumps. An unstable base causes vibration, leading to premature wear and potential failure. Operators should follow a precise process to secure the unit.

1.Place the pump on a concrete foundation and mark locations for anchor bolts.

2.Use wedge-shaped pads to adjust the level before tightening the bolts.

3.Fill the space between the foundation and the pump feet with concrete.

4.After the concrete cures, tighten the anchor bolts and recheck the pump’s level.

Important: Inlet and outlet pipes require their own support structures. The pump body should never bear the weight of the piping, as this creates strain and can damage the pump casing.

Hose and Pipe Configuration

The choice between rigid and flexible piping depends entirely on the application. Rigid pipes offer durability for permanent setups, while flexible hoses provide adaptability for temporary or complex layouts. The right choice minimizes friction loss and simplifies installation.

| Feature | Rigid PVC Pipe | Flexible PVC Pipe |

|---|---|---|

| Durability | High structural strength; resists corrosion. | Lower strength; prone to UV and physical damage. |

| Flexibility | Not designed to bend; for straight runs. | Highly flexible; easily routed around obstacles. |

| Installation | Requires more fittings for turns. | Reduces need for connectors; easy to assemble. |

| Best Use | Permanent underground or straight-line systems. | Temporary dewatering, irrigation, complex layouts. |

Priming and Safe Startup

Priming is the process of filling the pump casing and suction line with water to remove air before starting. Running a pump dry can cause immediate and severe damage to its seals and impellers.

Before every start, operators should perform a safety check:

·Verify the unit has the correct type and amount of fuel (typically No. 2 diesel).

·Ensure the water source is free of large stones or debris that could damage the pump.

·Confirm all hoses and pipes are securely connected and free of kinks.

·Check that the pump is properly mounted and grouted.

Some advanced vertical turbine pumps offer a significant advantage. Models like the Tongke pump can operate without pre-filling as long as their impellers are fully submerged in the water source.

Essential Maintenance for Longevity

Consistent maintenance is the key to ensuring a diesel pump’s reliability and long service life. A proactive approach prevents costly downtime and protects the investment. Operators should follow a structured schedule of daily checks, periodic service, and proper seasonal storage.

Daily and Weekly Checks

Routine visual inspections are the first line of defense against equipment failure. Operators should perform these checks before each use. A thorough inspection helps identify minor issues before they become major problems.

·Examine the pump and its surroundings for any signs of damage or fluid leaks. Puddles of liquid or a sweet coolant odor can indicate a system breach.

·Listen for unusual engine noises like grinding or whining, which may signal worn internal components.

·Verify the control panel is functioning correctly and all pressure gauges read within the specified range.

·Check the diesel fuel level and refill as needed.

·Confirm the water supply is clear of debris that could obstruct the intake.

·Maintain a detailed log of all maintenance activities and any corrective actions taken.

Scheduled Service Intervals

Adhering to manufacturer-recommended service intervals is critical for engine health and performance. These tasks involve replacing fluids and filters to keep the system running cleanly and efficiently. Service frequency may increase under severe or dusty conditions.

| Component | Standard Service Interval (Operating Hours) |

|---|---|

| Engine Oil | Every 100-250 hours |

| Fuel Filter | Inspect every 100 hours; replace every 300-500 hours |

| Air Filter | Inspect weekly; replace as needed |

More intensive service should occur at key milestones. At 250 hours, operators should change the engine oil and filter, inspect belts, and check the fuel/water separator. The 500-hour service includes these tasks plus a full coolant system check and inspection of the turbocharger and electrical connections.

Winterization and Storage

Proper storage protects the pump during periods of inactivity, especially in cold climates. Winterization prevents damage from freezing temperatures and fuel degradation.

Pro Tip: Always run the pump completely dry before storage. Any water left inside can freeze and crack the pump casing or internal components.

1.Manage the Fuel: Add a quality fuel stabilizer to a full tank of diesel. This prevents moisture buildup and microbial growth.

2.Protect the Battery: Disconnect the battery terminals to prevent a slow discharge. For long-term storage, remove the battery and keep it in a cool, dry place on a trickle charger.

3.Store Securely: Keep the unit in a dry, shaded location where temperatures remain stable. Cover the pump to protect it from dust and debris.

A properly selected and maintained diesel multistage pump is the definitive tool for managing remote water challenges. It delivers the power, high-pressure capability, and reliability needed for demanding off-grid environments. The versatility of a multistage pump even extends to specialized industrial uses, like creating self-contained heating systems for remote drilling sites. These systems prove the pump’s suitability for tough conditions.

Operators can take control of their remote water management needs. They should assess their head and flow rate requirements to select the right equipment today.

FAQ

What does “multistage” mean in a pump?

A multistage pump uses multiple impellers arranged in a series. Each impeller, or stage, progressively boosts the water pressure. This design gives the pump the power to move water over greater heights and longer distances than single-stage pumps.

Can these pumps handle water with sand or debris?

Yes, specialized models can manage solids. For instance, the Tongke vertical turbine pump offers abrasive-resistant impellers and muff armor tubing. These enhancements allow it to effectively pump water containing materials like fine sand or scrap iron without rapid wear.

Why are different material options like stainless steel important?

Material choice determines the pump’s durability and application. While cast iron is standard, premium options like stainless steel or bronze provide superior resistance to corrosion and abrasion. This extends the pump’s operational life, especially in harsh environments or with corrosive liquids.

Do all diesel pumps need to be primed before starting?

Most pumps require priming to prevent damage from running dry. However, some vertical turbine designs offer an advantage. These pumps can start safely without pre-filling as long as their impellers remain fully submerged in the water source.

Post time: Dec-23-2025