A fire fighting pump moves water at high pressure to help you control and extinguish fires. You rely on this device for a strong and steady flow of water, especially when the regular supply cannot meet emergency needs. Fire fighting pumps play a vital role in building safety and compliance.

|

Aspect |

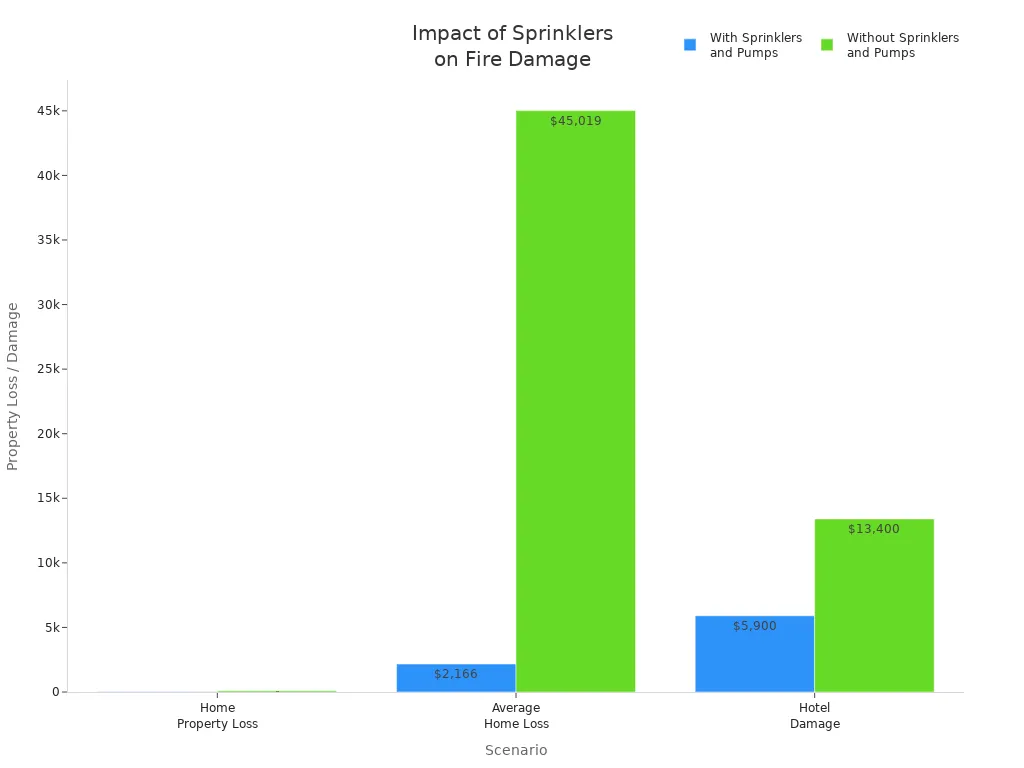

Impact of Fire Sprinklers and Pumps |

| Reduction in property loss in residences | Up to 85% less property loss compared to homes without sprinklers |

| Average fire loss in homes | $2,166 with sprinklers vs. $45,019 without |

| Reduction in property damage | Up to 97% reduction in fire damage |

| Reduction in civilian deaths | 60% to 91% reduction depending on property type |

Key Takeaways

● Fire fighting pumps boost water pressure to help control fires, especially when normal water supply is not enough.

● These pumps are vital for safety in tall buildings and large spaces, ensuring water reaches all areas quickly.

● Centrifugal pumps are common for high flow, while positive displacement pumps provide steady flow at high pressure.

● Regular testing and maintenance keep pumps ready for emergencies and help meet safety codes like NFPA 20 and 25.

● Choosing the right pump and power source, plus professional installation, ensures reliable fire protection when it matters most.

Fire Fighting Pump Basics

What Is a Fire Fighting Pump

A fire fighting pump is a mechanical device that moves water or fire suppression liquids to help put out fires. According to the National Fire Protection Association (NFPA), this pump is a key part of a fire protection system. It is designed, tested, and certified to deliver the right water pressure and flow to fire sprinkler systems, standpipes, and hydrants. You will often find these pumps powered by electric motors or diesel engines. They are used in places where the normal water supply cannot provide enough pressure to fight a fire.

You can see fire fighting pumps in many settings:

● High-rise buildings, where water must reach upper floors

● Storage warehouses, which need fast water delivery across large spaces

● Industrial plants, where pumps supply water to sprinklers and hoses

● Data centers, to protect sensitive equipment

● Commercial buildings like offices and shopping centers

Main Function

The main function of a fire fighting pump is to increase water pressure in a fire protection system. When a fire starts, the pump activates and boosts the water pressure and flow rate to the sprinklers. This ensures that water reaches every part of the building, even in high places or through long pipes. Without a fire fighting pump, the water pressure might not be strong enough to control or put out a fire. The pump draws water from a supply, such as a municipal source or a storage tank, and pushes it through the system at the needed pressure.

Importance in Fire Safety

A fire fighting pump plays a vital role in keeping buildings safe. It helps maintain the right water pressure for sprinklers and hydrants, which is especially important in tall buildings or large spaces. The pump ensures that water can travel far and high, overcoming gravity and friction in the pipes. This quick response can stop a fire from spreading, protect property, and save lives.

● Fire pumps are required by safety codes, such as NFPA 20, to make sure buildings meet fire safety standards.

● Regular testing and maintenance keep the pump ready for emergencies.

● Backup power sources, like diesel engines, allow the pump to work even during power outages.

Fire fighting pumps are not just important for safety—they are also necessary for meeting building codes and insurance requirements. When you have a reliable fire pump, you help protect people, property, and your investment.

How Fire Fighting Pumps Work

Working Principle

You can understand the operation of a fire fighting pump by looking at how it moves water. Most pumps use centrifugal force to increase water pressure and flow. Here is how a centrifugal pump works:

1.You fill the pump casing and suction pipe with water before starting.

2.The pump shaft rotates when the prime mover starts, causing the impeller and water to spin quickly.

3.Centrifugal force pushes the water outward from the center of the impeller to its edge.

4.Water enters the volute casing, where the pump converts some of the water’s speed into pressure.

5.A vacuum forms at the center of the impeller as water moves out.

6.Atmospheric pressure pushes more water from the source into the impeller center.

7.This cycle continues, delivering water at high pressure through the outlet pipe.

Positive displacement pumps work differently. They trap and move fixed amounts of water with each cycle. This design keeps the flow rate steady, even if the pressure changes. You often see these pumps in systems that need precise control or very high pressure.

Key Components

A fire fighting pump system includes several important parts. Each part helps the pump work reliably and safely:

1.Fire Pump – This is the main device that increases water pressure. You may find centrifugal or positive displacement types.

2.Pump Driver – This powers the pump. You can use an electric motor, diesel engine, or steam turbine.

3.Controller – This device starts and stops the pump automatically and monitors its status.

4.Suction Piping – Pipes bring water from the source to the pump. Strainers and check valves keep debris out and prevent backflow.

5.Discharge Piping – These pipes carry pressurized water to sprinklers, hydrants, or hoses. Valves and flowmeters help control and measure flow.

6.Pressure Relief Valve – This valve releases extra pressure to protect the system.

7.Jockey Pump – A small pump keeps the system pressurized during normal conditions, so the main pump does not run unnecessarily.

8.Fire Pump House – This enclosure protects the pump and its equipment from weather and damage.

9.Flow and Pressure Monitoring Devices – These tools track system performance and trigger alarms if something goes wrong.

10.Valves – You use these to control water flow and prevent backflow.

11.Expansion Tank – This tank absorbs changes in pressure.

12.Fuel Supply – Diesel engines need a steady supply of fuel for reliable operation.

13.Alarm and Monitoring System – This system alerts you to problems or when the pump activates.

The impeller and casing play a big role in pump performance. The split casing design makes maintenance easier and reduces downtime. The casing guides water smoothly, lowering friction and boosting efficiency. A double-suction impeller balances forces inside the pump, making it stable even at high pressure.

|

Feature |

Centrifugal Pumps |

Positive Displacement Pumps |

| Mechanism | Rotating impeller creates continuous flow. | Moves fixed volumes per cycle for constant flow. |

| Flow Characteristics | Flow rate changes with pressure. | Flow rate stays steady, even if pressure changes. |

| Pressure Generation | Good for moderate pressures. | Can create high pressures consistently. |

| Fluid Handling | Best for thin liquids. | Handles thick or sensitive fluids well. |

| Application in Firefighting | Ideal for sprinklers and general suppression. | Used for metering and special high-pressure needs. |

| Additional Considerations | Simple, low maintenance. | Needs pressure relief valves for safety. |

Power Sources

You can choose from several power sources for your fire fighting pump. Each option has strengths and weaknesses.

● Electric fire pumps are common in commercial buildings. They cost less, need less maintenance, and run quietly. You must have a reliable power supply, or a backup generator, because these pumps stop working during outages. About 58.3% of fire fighting pumps in commercial buildings use electric power.

● Diesel fire pumps work even if the electricity fails. They are reliable and often used in places where power outages are a risk. You need to store fuel and provide ventilation. These pumps cost more and require regular maintenance and testing.

● Steam-powered pumps are rare today. You may see them in older facilities, but most modern systems use electric or diesel engines.

|

Power Source |

Advantages |

Disadvantages |

| Electric | Low maintenance, simple design, suitable for outdoor use | Depends on power supply, needs backup generator in critical areas |

| Diesel | Reliable during power outages, independent of grid | Needs fuel storage, ventilation, higher cost, more maintenance |

| Steam | Historic use | Rarely used, mostly for nostalgia |

You should always follow standards like NFPA 20 when choosing and installing a pump power source. Backup power and automatic transfer switches help keep your fire fighting pump ready for emergencies.

Types of Fire Fighting Pumps

Centrifugal Pumps

You will find centrifugal pumps in most fire protection systems. These pumps use a spinning impeller to move water and create pressure. When you need to move large amounts of water quickly, centrifugal pumps work best. Their flow rate changes if the pressure in the system changes. This makes them ideal for sprinklers and hydrants in buildings where you need high flow but not extreme pressure.

|

Pump Type |

Description & Features |

Typical Applications |

Advantages |

Limitations |

| Horizontal Split-Case | Rugged, efficient, easy maintenance due to split casing; requires floor space | Large commercial and industrial buildings | Long life, dependable, easy to maintain | Needs considerable floor space |

| Vertical Turbine | Designed for deep water sources; lifts water from reservoirs, lakes, wells | High-rise buildings, rural areas | High pressure, smooth performance | Requires vertical space, complex installation |

| In-Line | Compact, installed directly in piping; space-saving | Commercial buildings, residential systems | Easy installation, low maintenance | Less powerful, not for large-scale systems |

| End Suction | Low cost, simple, space-efficient | Small fire protection systems (offices, stores) | Easy to install, low maintenance | Not suitable for high pressure or high-rise |

| Multistage Multiport | Multistage design for high pressure and flow; used in very large buildings | Multi-story buildings, factories | High efficiency at high pressure | Complex, costly, requires specialized service |

| Vertical In-Line Fire Pump | Vertical compact design with motor and pump aligned; saves floor space | Small buildings, limited space | Space-saving, easy installation | Maintenance can be complicated |

| Jockey Pump | Small pump maintaining system pressure to prevent main pump cycling | All fire pump systems | Maintains pressure, reduces wear on main pump | Not used directly for firefighting |

Centrifugal pumps are the most common type in fire protection because they handle high flow rates and are easy to maintain.

Positive Displacement Pumps

Positive displacement pumps move a fixed amount of water with each cycle. You can count on them for steady flow, even if the pressure changes. These pumps work well when you need high pressure or precise control, such as in special fire fighting vehicles or systems with thick liquids. Types include piston, rotary, and diaphragm pumps. Diaphragm pumps can even handle water with debris.

● Positive displacement pumps provide constant flow, no matter the pressure.

● They are best for high-pressure, low-flow needs.

● You will see them in situations where accurate dosing or handling of dirty water is important.

Portable Fire Pumps

Portable fire pumps give you flexibility during emergencies. Firefighters use them when fixed systems cannot reach the fire or when water sources are far away. You can carry or wheel these pumps to lakes, rivers, or other water sources. They help supply water to hoses or fill tanks quickly.

● Portable pumps come in different sizes and types, such as small hand-carried units or trailer-mounted models.

● You can use them for wildland fires, urban fires, or even to remove water from flooded areas.

● Regular drills and maintenance keep these pumps ready for action.

System Configurations

You can choose from single-stage or multi-stage fire fighting pump systems. Single-stage pumps have one impeller and work well for high flow at lower pressure. Multi-stage pumps use two or more impellers to boost pressure, making them perfect for tall buildings or long hose runs.

● Single-stage: Simple, less costly, easy to maintain.

● Multi-stage: Higher pressure, more complex, better for high-rise or large systems.

Jockey pumps keep the system pressurized during normal times. Backup pumps, often powered by diesel, provide extra reliability if the main pump fails. These features help your fire fighting pump system stay ready and dependable.

Installation and Maintenance

Professional Setup

You should always use certified professionals for installing fire fighting pumps. Proper installation follows the National Fire Protection Association (NFPA) 20 standard, which covers pump selection, placement, and operational requirements. NFPA 13 and NFPA 22 also provide important guidelines for sprinkler systems and water tanks. Certified pumps, such as those with UL 448 or FM Approvals, meet strict safety and performance standards. Professionals will select the right pump type, align it correctly, and ensure it sits on a stable foundation. They also install pumps in dedicated, protected spaces with reliable power supplies and backup generators. This setup prevents failures, supports safety, and meets legal requirements.

Routine Inspections

Regular inspections keep your fire fighting pump ready for emergencies. NFPA 25 outlines how often you should inspect and test your system. The table below shows the recommended intervals:

|

Fire Pump Type |

Inspection/Test Interval |

Description |

| Diesel Fire Pumps | Weekly | Run a no-flow test for 30 minutes to check operation, engine lubrication, and battery. |

| Electric Fire Pumps | Monthly | Run a no-flow test for 10 minutes, checking pressures, noises, and overheating. |

| All Fire Pumps | Annually | Perform a full-capacity flow test and compare results to manufacturer specs. |

You should also inspect control valves, alarms, and gauges monthly. Test water flow alarms and signal devices every quarter. Schedule annual tests for all key components.

Maintenance Tips

Good maintenance prevents most pump failures. You should:

1.Lubricate moving parts and replace worn seals or bearings.

2.Clean strainers and suction lines to avoid clogs.

3.Check for leaks, corrosion, and abnormal vibrations.

4.Test electrical systems and backup power supplies.

5.Keep detailed records of all inspections and repairs.

6.Train your staff to spot problems early and follow safety rules.

Testing and Compliance

Testing Procedures

You need to test your fire fighting pump regularly to make sure it works when you need it most. Testing follows a set schedule and covers many important steps. Qualified personnel should always perform these tests. Here is what you should expect:

Weekly Checks

① Inspect the pump room for leaks, cleanliness, and easy access.

② Look at the pump, motor, and all parts for damage or wear.

③ Run diesel pumps for 30 minutes with no water flow.

④ Check pipes, valves, and fittings for leaks or corrosion.

⑤ Record and report everything you find.

Monthly Checks

⑥ Run electric pumps for at least 10 minutes.

⑦ Measure suction and discharge pressures.

⑧ Listen for strange noises or vibrations.

⑨ Check the pump casing and bearings for overheating.

⑩ Inspect electrical voltage and amperage.

⑪ Write down all results.

Annual Tests

⑫ Perform full flow tests at 100% and 150% capacity.

⑬ Test alarm signals and supervisory functions.

⑭ Inspect all pump parts for wear, corrosion, and leaks.

⑮ Review system documents and maintenance records.

⑯ Update emergency procedures and train staff.

⑰ Keep detailed records of every test and fix.

|

Activity Type |

Description |

Frequency |

| Inspection | Check pump assembly condition | Weekly |

| Test (No-flow/Churn) | Electric pump operation test | Weekly |

| Test (Operational Run) | Diesel pump operation test | Weekly |

| Test (Flow Test) | Performance testing at various flows | Annually |

| Maintenance | Preventive maintenance | Annual typical |

Regulatory Standards

You must follow strict codes to keep your fire fighting pump system compliant. In the United States, NFPA 20 sets rules for design, installation, and acceptance testing of new pumps. NFPA 25 covers ongoing inspection, testing, and maintenance. These standards require weekly no-flow tests for diesel pumps and annual flow tests for all pumps. You also need to test alarm and signal systems to make sure they work during emergencies.

If you own a vessel, U.S. Coast Guard rules in Title 46 CFR add extra requirements. These include installing pressure gauges and separating pumps to prevent total loss in a fire.

International standards, such as BS EN 12845 and LPCB, focus more on individual pump components. NFPA 20 is more detailed and covers the whole system, making it the most stringent. Many countries use NFPA 20 as a reference for their own codes.

|

Aspect |

U.S. Standard (NFPA 20) |

International Standards (BS EN 12845, LPCB) |

| Scope | Covers entire fire pump room and system | Focuses on individual components |

| System Integration | Requires system-wide performance and compatibility | Components certified individually |

| Specificity on Pump Components | Detailed requirements for pump, driver, controller | Less detail on drivers and controllers |

| Adoption and Influence | Most stringent; widely adopted | Often defers to NFPA 20 |

Fire fighting pumps protect your building and everyone inside. You need to choose the right pump, install it correctly, and keep it well maintained. Regular checks help you stay ready for emergencies.

● Always talk to a fire protection professional before making changes to your system. They help you follow safety codes and keep your property safe.

● Make fire safety a top priority in every facility.

● Stay prepared and protect what matters most.

FAQ

What triggers a fire fighting pump to start?

Your fire fighting pump starts when the system detects a drop in water pressure. This usually happens when a sprinkler or hydrant opens during a fire. The pump activates automatically to boost water flow.

How often should you test your fire fighting pump?

You should test your fire fighting pump weekly or monthly, depending on the type. Diesel pumps need weekly tests. Electric pumps need monthly tests. Annual flow tests check full performance.

Can you use a fire fighting pump for other purposes?

You should only use your fire fighting pump for fire protection. Using it for other tasks can damage the pump or make it unavailable during emergencies.

What happens if the power goes out during a fire?

Your system may use a diesel engine or backup generator to keep the pump running. This ensures water flows even if electricity fails.

|

Power Source |

Backup Needed? |

| Electric | Yes |

| Diesel | No |

How do you know if your fire fighting pump is working properly?

You can check gauges, listen for unusual noises, and look for leaks. Regular inspections and tests help you spot problems early.

● Always follow NFPA guidelines

● Train staff to recognize warning signs

Post time: Aug-21-2025