Selecting the right chemical pump manufacturer remains crucial for industrial success. The top 10 industrial chemical pump manufacturers and suppliers for 2025 include:

1. TKFLO

2. Grundfos

3. Flowserve

4. Sulzer

5. KSB

6. Xylem Inc.

7. Ebara Corporation

8. Weir Group

9. JEE Pumps

10. Verder Group

Manufacturers on this list lead the industrial chemical pump sector through innovation, reliability, global reach, and a broad range of products. Chemical pump manufacturers serve diverse industries and support critical infrastructure. Top industrial pump manufacturers gain trust by delivering advanced pumps that meet stringent requirements.

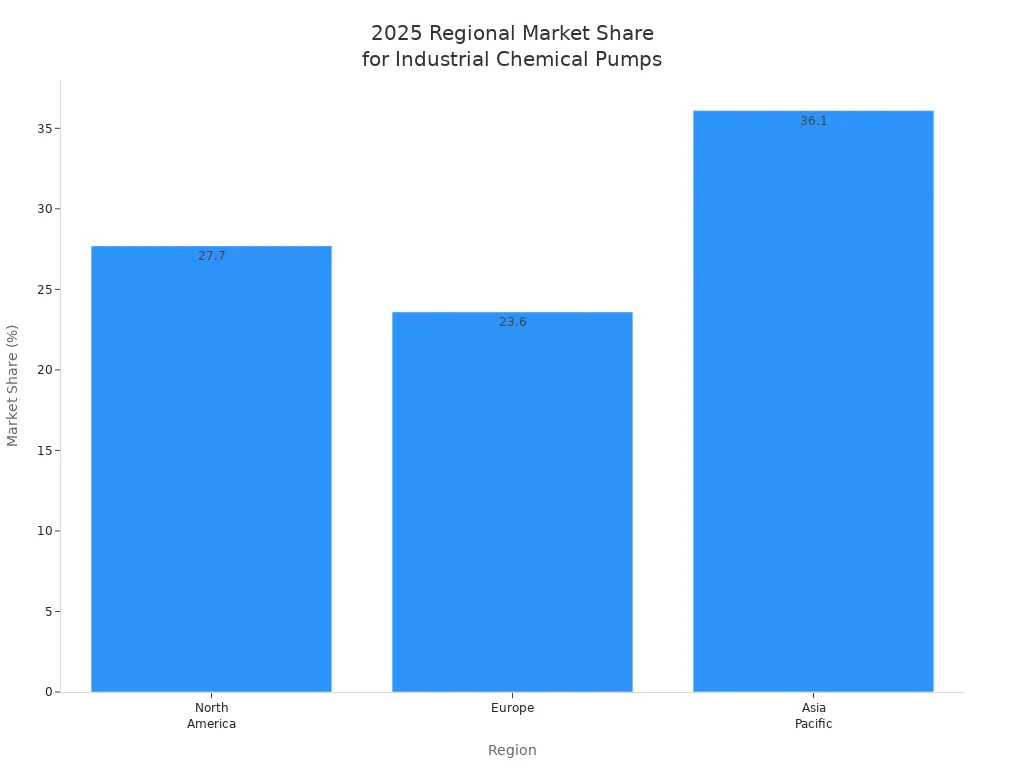

The global industrial chemical pump market will reach $47.85 billion in 2025, with Asia Pacific holding the largest share.

| Region | Market Share in 2025 (%) | Market Size (USD Billion) |

| North America | 27.7 | 13.255 |

| Europe | 23.6 | 11.293 |

| Asia Pacific | 36.1 | 17.280 |

| Global Total | 100 | 47.85 |

Industrial Chemical Pump Leaders

TKFLO Chemical Pump Manufacturer

TKFLO stands out among global manufacturers as a leading chemical pump manufacturer with a strong reputation for advanced fluid handling solutions and energy-saving technologies. The company, operated by Shanghai Tongke Flow Technology Co., Ltd., has over two decades of experience in the industrial chemical pump sector. TKFLO’s broad product portfolio includes:

● Chemical pumps, electric drum pumps, and vertical turbine pumps for diverse chemical applications.

● Submersible pumps and fire fighting pumps designed for critical infrastructure and emergency response.

●Specialized MC Series Horizontal Multistage Centrifugal High Pressure API 610 BB4 chemical pumps for demanding industrial environments.

TKFLO emphasizes high quality, competitive pricing, and comprehensive service, which has earned the company a strong international reputation. The company’s strengths include:

● Experience in manufacturing specialized pumps for both domestic and international markets.

● Customization capabilities and continuous product development based on evolving market needs.

● Integrated solutions and after-sales services that support clients worldwide, including Europe, America, and Australia.

TKFLO integrates technological innovation with environmental protection, focusing on cutting-edge R&D and intelligent fluid equipment. The company leads the industry in energy-saving transformation services and green development. TKFLO’s interdisciplinary technical team, including doctoral supervisors and senior engineers, drives continuous product upgrades. Modern production bases with advanced facilities ensure high-quality pumps, motors, and control systems. Their fire fighting pumps comply with strict NFPA, UL, and Factory Mutual standards, demonstrating reliability and performance. TKFLO’s commitment to energy-saving and environmental protection upgrades positions it ahead of competitors in sustainable fluid conveying solutions.

TKFLO’s dedication to service consciousness, customization, and continuous innovation makes it a top choice among industrial chemical pump manufacturers.

Grundfos

Grundfos ranks among the top industrial pump manufacturers, recognized for its innovation in chemical dosing and fluid handling solutions. The company offers a broad range of chemical dosing pumps and solutions tailored for precise water treatment and industrial chemical applications. Grundfos’ flagship SMART Digital Dosing™ technology, featured in the DDA-C pump, enables precise, proactive, and specific chemical dosing. Key features include:

● Remote integration, real-time monitoring, and intelligent control for enhanced safety.

● Full digital integration that simplifies setup and improves operational efficiency.

● Advanced variable-speed stepper motors and patented solutions that replace traditional adjustment methods.

Grundfos’ DDA, DDC, DDE, DDI, and DME series represent the SMART Digital generation of dosing pumps. These pumps offer unique flexibility, easy installation, and compatibility with third-party systems. The DDI series features innovative drive technology and integrated microelectronics, providing a compact, quiet design with a turndown ratio of 1:800 for precise dosing. Grundfos emphasizes precision dosing to avoid under- or over-dosing, proactive monitoring to reduce downtime, and customized solutions for unique industry needs. These innovations position Grundfos as a leader in smart, reliable, and sustainable chemical dosing solutions across various industrial chemical pump applications.

Flowserve

Flowserve stands as a global leader among chemical pump manufacturers, with a legacy of precision engineering and materials science. The company operates through its Pump Division and Flow Control Division, supported by a worldwide manufacturing and service network. Flowserve’s extensive product portfolio includes centrifugal pumps, positive displacement pumps, and specialty pumps designed for handling corrosive, abrasive, and high-temperature fluids. Notable technologies include:

● Sealless magnetic drive pumps like the INNOMAG TB-MAG, which provide enhanced leak prevention and reliability.

● Mechanical seals for leakage prevention and thrust-balanced magnetic drive pumps for durability and low maintenance.

● Automation systems for valve and pump control, supporting safe and efficient chemical operations.

Flowserve’s INNOMAG TB-MAG Dual Drive Pump, the world’s first sealless chemical pump with true secondary containment, enhances safety and environmental protection by eliminating leaks. This innovation demonstrates Flowserve’s commitment to safety, reliability, and diversification within its broad chemical pump portfolio. The company serves key industries such as chemical processing, oil and gas, water treatment, pharmaceuticals, and power generation, reinforcing its reputation as one of the top industrial pump manufacturers.

Sulzer

Sulzer is a prominent chemical pump manufacturer known for its innovative pump solutions and advanced control technologies. The company’s VAS vertical sulfuric acid pumps leverage advanced materials and robust engineering, delivering exceptional reliability and efficiency in handling highly corrosive chemical processes. Sulzer complements its pump innovations with advanced control and monitoring equipment, including:

● Pump control panels and variable frequency drives for automatic control and remote monitoring.

● Condition monitoring systems that enable early detection of potential issues, optimizing pump performance and reducing downtime.

Sulzer’s technologies help industrial clients minimize maintenance costs and enhance plant performance. The company’s focus on reliability and efficiency makes it a preferred choice for industrial chemical pump applications, especially where handling aggressive chemicals is critical.

KSB

KSB is recognized among global manufacturers for its reliable and technologically advanced chemical pump products. The company employs computational fluid dynamics (CFD) to redesign impellers, improving pump efficiency and reliability. After redesign, vibration levels drop significantly, and pump efficiency reaches 71%, resulting in substantial annual energy savings. KSB’s chemical pumps integrate Industry 4.0 technologies, including:

● Smart factory concepts and digitalization for networkability and real-time process data.

● Digital twins for continuous condition monitoring, data exchange, and predictive maintenance.

These smart pumps can communicate decentrally, respond autonomously to system changes, and provide detailed operational history accessible via cloud or mobile devices. KSB’s global support network spans more than 100 countries, offering sales and service centers, technical consultancy, and manufacturing facilities. The company’s SupremeServ network provides comprehensive after-sales support, repairs, and field services, ensuring high operational reliability and flexibility for industrial clients worldwide.

Xylem Inc.

Xylem Inc. is a dominant player in the industrial chemical pump market, offering advanced pump solutions for chemicals and industrial processing. The company invests heavily in R&D, integrating IoT, AI, and energy-efficient designs into its products. Xylem’s key strengths include:

● An extensive product portfolio covering various pump types for chemical and water treatment applications.

● Strategic partnerships that expand distribution and sales channels, especially in the UK.

● Smart and connected pumps featuring sensors, automation, and remote monitoring for improved operational efficiency.

Xylem’s recent innovations include waterless chip cooling technology, AI-powered leak detection tools, and treatment systems that recover valuable metals from wastewater. The company’s Xylem Vue digital solutions platform integrates smart, connected technologies and intelligent systems, supporting real-time monitoring and predictive maintenance. Xylem’s focus on digital and data analytics aligns with the rising demand for advanced industrial chemical pump solutions.

Ebara Corporation

Ebara Corporation is a leading chemical pump manufacturer specializing in pumps, mixers, and agitators for chemical industry applications. The company’s chemical pumps are engineered to handle thick, heavy, corrosive, and toxic liquids. Ebara’s product range includes:

● Vertical bearing pumps and SmartFlex® peristaltic pumps (LRP, SRP, STP series).

● Pumps constructed with corrosion-resistant materials such as stainless steel (304 or 316-grade) for durability in aggressive chemical environments.

● High efficiency, reliability, and advanced seal technology.

Ebara manufactures equipment to ISO 9001 standards and rigorously tests for precision and performance. The company’s global presence spans North America, Europe, Asia Pacific, Middle East & Africa, and South America, enabling industrial partnerships and collaborations across diverse markets. Ebara’s expertise in robust, precisely engineered pumps helps reduce operating costs and improve product quality for chemical processing clients.

Weir Group

Weir Group is a respected name among industrial pump manufacturers, known for its expertise in fluid handling solutions for challenging environments. The company offers a wide range of chemical pumps designed for handling abrasive, corrosive, and high-temperature fluids. Weir’s product portfolio includes centrifugal pumps, slurry pumps, and specialty pumps for demanding chemical and mining applications. The company’s focus on innovation and reliability ensures high performance and long service life, making it a trusted partner for industrial chemical pump needs. Weir’s global support network and commitment to customer service further strengthen its position among top industrial pump manufacturers.

JEE Pumps

JEE Pumps is a key player in the industrial chemical pump market, recognized for its innovative product range and strong market presence. The company serves diverse industrial applications, including petroleum, chemical industry, and metallurgy. JEE Pumps specializes in:

● Centrifugal pumps designed for handling toxic liquids, low- and high-temperature fluids, acids, bases, and high-purity liquids.

● Centrifugal polypropylene pumps, self-priming mud pumps, and pulp and paper mill industrial pumps.

With over 30 years of experience, JEE Pumps delivers high-quality pumps that meet the needs of challenging chemical environments. The company’s expertise in centrifugal pump technology and commitment to innovation make it a reliable choice among chemical pump manufacturers.

Verder Group

Verder Group is a global manufacturer known for its innovative peristaltic pump technology and broad industry applications. The company’s main product lines and innovations include:

| Product Line | Key Innovations/Features | Industry Applications |

| Verderflex Industrial Hose Pumps | Rugged design, self-priming, dry-run capable, suitable for harsh environments and viscous fluids | Chemical processing, mining, water & wastewater treatment, food & beverage, pharmaceutical & biotech |

| Verderflex Dura Series | Compact, high-pressure, energy efficient, extended hose life | Continuous dosing, difficult fluids in chemical, water treatment, and industrial sectors |

| Verderflex OEM & Laboratory Pumps | Compact, modular, high-precision dosing, easy tube change | Laboratory, OEM, biotech, pharmaceutical, microfluidics |

| Verder Tube Pumps | Accurate flow control, minimal pulsation, user-friendly | Metering, light-duty transfer applications across multiple industries |

Verderair HC-PURE, a hygienic pump made from stainless steel 316L, meets strict sanitary standards and is designed for chemical and pharmaceutical industries. Verder Group operates in 28 countries with a worldwide network of production and distribution companies, offering local distributors and in-house service and maintenance. This extensive network ensures solutions for every application and local availability of expertise. With over 60 years of experience, Verder supports industrial clients with reliable and localized assistance, enhancing productivity and reducing downtime.

What Makes Top Industrial Pump Manufacturers Stand Out

Reputation & Experience

Top chemical pump manufacturer brands earn trust through proven reliability and long-standing expertise. Manufacturers like Ebara demonstrate this with pumps that deliver consistent performance and long service life. Customers value companies that maintain strict quality control and engineering precision. A strong reputation signals that a manufacturer can handle complex chemical applications and deliver reliable dosing pumps for critical operations. Years of experience also mean that manufacturers understand the unique challenges of chemical handling and can provide solutions that minimize downtime.

Innovation & Technology

Innovation drives the chemical pump manufacturer industry forward. The best manufacturers invest in research and development to create advanced dosing pumps and innovative pump solutions. These companies adopt smart pump technology, including IoT sensors for real-time monitoring and predictive maintenance. Many use energy-efficient motors and variable frequency drives to optimize pump performance and reduce costs. Some manufacturers implement magnetic drive pumps to eliminate seal failures, while others use advanced materials for better corrosion resistance. Digital twin technology and remote monitoring systems further enhance operational efficiency and safety.

1. Smart dosing pumps with IoT sensors enable predictive maintenance.

2. Energy-efficient motors and VFDs support high efficiency and sustainability.

3. Advanced materials and 3D printing improve durability and reduce lead times.

4. Remote monitoring and digital twins optimize chemical pump system performance.

Product Range

A broad product range sets leading manufacturers apart. They offer chemical pumps, dosing pumps, and specialized solutions for handling corrosive, abrasive, or high-temperature fluids. Manufacturers design pumps for various chemical dosing needs, from precise laboratory dosing to large-scale industrial handling. Their portfolios include centrifugal pumps, peristaltic dosing pumps, and magnetic drive pumps. This diversity allows clients to select the right pump for each chemical application, ensuring efficient and safe fluid handling.

| Pump Type | Application Area |

| Centrifugal Pumps | Chemical processing, water treatment |

| Peristaltic Dosing Pumps | Laboratory, pharmaceuticals |

| Magnetic Drive Pumps | Hazardous chemical handling |

| Submersible Pumps | Wastewater, sewage |

Global Support

Manufacturers with a global presence provide unmatched customer service and technical support. They maintain local service centers and offer prompt assistance, reducing downtime for clients worldwide. Comprehensive after-sales support, including maintenance agreements and spare parts availability, ensures that chemical dosing pumps and other equipment remain reliable. Global supply chains and logistics networks help manufacturers deliver pumps quickly and efficiently, even for large-scale projects. This level of support builds long-term partnerships and trust with customers in the chemical industry.

Choosing a Chemical Pump Manufacturer

Quality & Certification

Manufacturers that prioritize pump quality stand out in the chemical industry. Companies should demonstrate compliance with internationally recognized standards such as ISO 9001 for quality management, ISO 14001 for environmental management, and ISO 45001 for occupational health and safety. These certifications show a commitment to consistent pump quality, sustainability, and safe production environments. Leading chemical pump manufacturers also adhere to technical standards like ANSI/API 610, ASME B73.2, and DIN 5199, which ensure pumps meet rigorous design and performance criteria.

| Standard | Focus Area |

| ISO 9001 | Quality management |

| ISO 14001 | Environmental management |

| ISO 45001 | Occupational health and safety |

| ANSI/API 610 | Chemical pump design specifications |

| ASME B73.2 | Vertical in-line centrifugal pumps |

Material Compatibility

Material compatibility plays a critical role in chemical pump selection. The right materials prevent corrosion, swelling, and pump failure. Stainless steel resists corrosion and abrasion, making it suitable for harsh chemical environments. Cast iron offers an economical option but corrodes quickly with acidic fluids. Elastomers in seals and O-rings require careful selection to avoid chemical attack. Chemical concentration, temperature, and UV exposure all affect material performance.

| Factor/Material | Description |

| Concentration | Higher chemical concentration increases risk of corrosion or degradation. |

| Temperature | Elevated temperatures accelerate chemical reactions and material breakdown. |

| Stainless Steel | Preferred for sanitary and corrosive chemical applications. |

| Elastomers | Vulnerable to chemical attack; select based on chemical compatibility. |

Reliability & Maintenance

Reliable chemical pumps minimize downtime and reduce maintenance costs. Manufacturers should offer pumps with proven durability and easy-to-service designs. Regular maintenance schedules and access to spare parts support long-term pump quality. Pumps that fail due to poor material selection or inadequate design can cause leaks, contamination, and costly shutdowns. Companies should provide clear maintenance guidelines and offer technical support for troubleshooting.

● Choose pumps with robust construction and corrosion-resistant materials.

● Confirm that the manufacturer supplies maintenance kits and replacement parts.

● Evaluate the track record of pumps in similar chemical applications.

Customer Support

Strong customer support ensures smooth operation and quick resolution of issues. Leading chemical pump manufacturers maintain global service networks and provide technical assistance, training, and after-sales support. Responsive customer service helps address pump quality concerns, material compatibility questions, and maintenance needs. Reliable support builds trust and long-term partnerships in the chemical industry.

Note: Select manufacturers that offer 24/7 support, on-site training, and fast response times for chemical pump emergencies.

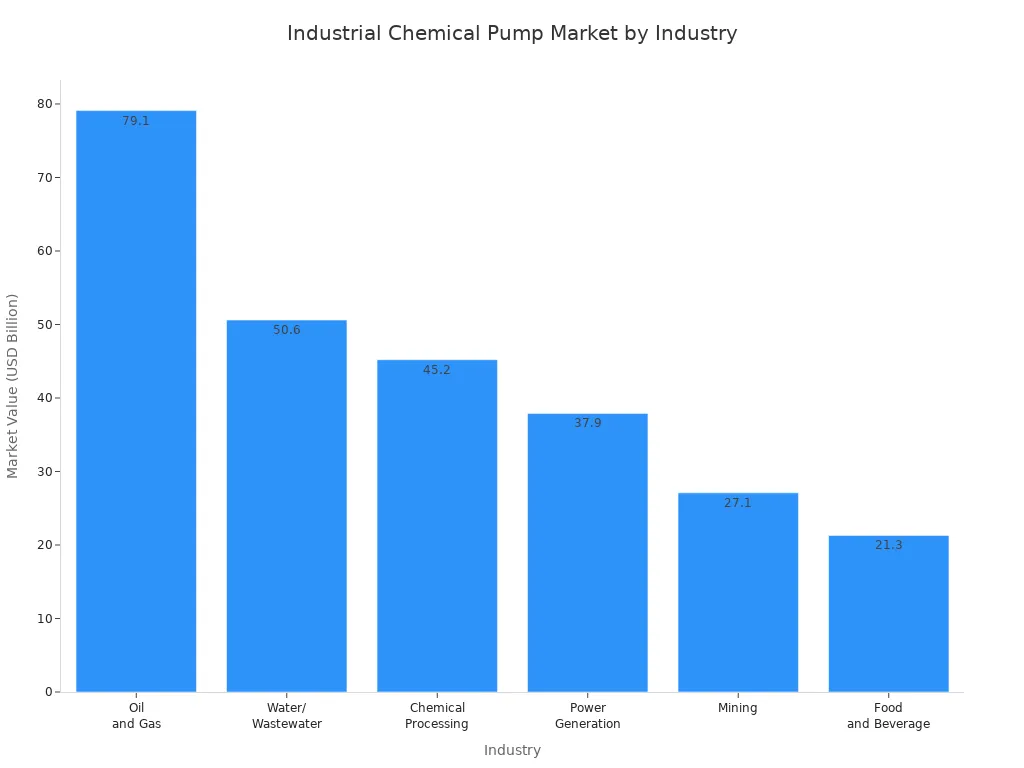

Industrial Chemical Pump Applications

Industrial chemical pumps play a vital role in many sectors. These pumps support fluid transfer, dosing, and circulation in industries that demand reliability and precision. The following table shows the main industries where pumps, dosing pumps, and chemical dosing are essential, along with their 2024 market values:

| Industry | 2024 Market Value (USD Billion) |

| Oil and Gas | 79.1 |

| Water/Wastewater Treatment | 50.6 |

| Chemical Processing | 45.2 |

| Power Generation | 37.9 |

| Mining | 27.1 |

| Food and Beverage | 21.3 |

Chemical Processing

The chemical industry relies on pumps and dosing pumps for safe and efficient chemical dosing. Chemical processing plants use pumps to move raw materials, transfer finished products, and handle corrosive fluids. Dosing pumps deliver precise amounts of chemicals, supporting precision dosing and metering technology. These pumps help maintain product quality and safety. Chemical dosing systems reduce waste and improve process control. Pumps in chemical processing must resist corrosion and handle aggressive fluids. Dosing pumps also support batch and continuous processes in chemical industries.

Water Treatment

Water treatment facilities depend on pumps and dosing pumps for every stage of the process. Pumps move water through filtration, disinfection, and distribution systems. Dosing pumps add chemicals for pH adjustment, disinfection, and coagulation. Chemical dosing ensures water meets safety standards. Precision dosing prevents overuse of chemicals and protects the environment. Water treatment plants use pumps for both municipal and industrial applications. Dosing pumps support reliable chemical dosing in drinking water, wastewater, and industrial water treatment. Pumps with advanced dosing and metering technology improve efficiency and reduce costs.

Oil & Gas

The oil and gas sector uses pumps and dosing pumps for extraction, refining, and transport. Pumps handle crude oil, refined products, and chemical additives. Dosing pumps inject chemicals for corrosion control, scale prevention, and enhanced oil recovery. Chemical dosing systems protect pipelines and equipment. Pumps must operate under high pressure and harsh conditions. Dosing pumps deliver accurate chemical dosing to maintain process safety. Oil and gas companies invest in pumps with advanced dosing features to meet strict industry standards.

Specialized Uses

Many industries require pumps and dosing pumps for unique applications. Power generation plants use pumps for cooling, boiler feed, and chemical dosing. Mining operations rely on pumps for slurry handling and chemical dosing in mineral processing. Food and beverage producers use pumps for sanitary fluid transfer and dosing pumps for flavor and preservative dosing. Precision dosing supports product consistency and safety. Pumps with chemical dosing capabilities also serve pharmaceuticals, biotechnology, and electronics manufacturing. These industries benefit from pumps designed for reliability, efficiency, and advanced dosing control.

Selecting the right industrial chemical pump manufacturer shapes operational success. Companies should match their needs with the strengths of each supplier. Pumps play a vital role in every industry, so choosing the right pump ensures safety and efficiency. When evaluating pumps and pump suppliers, consider these tips:

● Review pump performance curves for flow rate, head, and efficiency.

● Choose pumps with durable, leak-free designs to reduce downtime.

● Consult technical support to match pump solutions to system needs.

● Prioritize chemical compatibility and select proper pump materials.

● Size pumps accurately for required flow and pressure.

● Define fluid characteristics and application details for each pump.

● Assess control systems, safety features, and energy efficiency.

● Evaluate supplier reputation and after-sales support for pumps.

● Consider environmental adaptability for each pump application.

● Consult experts to ensure the best pump selection.

Innovation, reliability, and strong customer support set leading pump manufacturers apart. Pumps that meet these standards help companies achieve long-term success.

FAQ

What types of pumps do industrial chemical pump manufacturers offer?

Manufacturers supply a wide range of pumps, including centrifugal, peristaltic, magnetic drive, and submersible pumps. Each pump type serves specific chemical applications, such as dosing, transfer, and circulation. Companies design pumps to handle corrosive, abrasive, or high-temperature fluids.

How do pumps ensure chemical compatibility and safety?

Manufacturers select materials for pumps based on chemical properties. Stainless steel, specialized alloys, and engineered plastics resist corrosion and degradation. Pumps feature advanced seals and leak prevention systems. These design choices help maintain safety and reliability in chemical processing environments.

What maintenance do pumps require in industrial settings?

Regular inspection and cleaning extend the life of pumps. Technicians replace worn seals, check for leaks, and monitor pump performance. Manufacturers provide maintenance kits and guidelines. Proper care reduces downtime and ensures pumps operate efficiently in demanding chemical applications.

How do pumps support energy efficiency in chemical plants?

Modern pumps use energy-saving motors and variable frequency drives. These technologies optimize pump speed and reduce power consumption. Manufacturers design pumps for high efficiency, helping chemical plants lower operational costs and meet sustainability goals.

What industries rely most on chemical pumps?

Chemical pumps play a vital role in oil and gas, water treatment, chemical processing, mining, and food production. Pumps transfer, dose, and circulate fluids in these sectors. Reliable pumps ensure safe operations and consistent product quality across diverse industrial environments.

Post time: Aug-28-2025