Analysis of technical specifications and engineering key points for installation of eccentric reducer in fire pump system

1.Configuration specification of outlet pipeline components

According to the mandatory provisions of the GB50261 "Code for Construction and Acceptance of Automatic Sprinkler System":

Core Component Configuration:

● A check valve (or multi-function pump control valve) must be installed to prevent the backflow of the medium

● A control valve is required for flow regulation

● Double monitoring of the working pressure gauge and the pressure gauge of the main outlet pipe of the system

Pressure Monitoring Requirements:

● The pressure gauge should be equipped with a buffer device (diaphragm buffer is recommended)

● Plug valve installed in front of the buffer device for easy maintenance

● Pressure gauge range: 2.0-2.5 times the working pressure of the system

2. Installation guidelines for fluid control devices

Directionality Requirements:

● Check valves/multi-function control valves should be strictly consistent with the direction of water flow

● Flange connection is recommended to ensure tightness

Pressure gauge installation details:

● Corrosion-resistant materials (304 stainless steel or copper alloy) should be used for buffer devices

● The operating height of the plug valve should be 1.2-1.5m from the ground

3.Optimization scheme of suction pipe system

Filter device configuration:

● The suction pipe should be equipped with a basket filter (pore size≤3mm)

● The filter should be equipped with a differential pressure alarm device

Designed for ease of maintenance:

● The filter should be equipped with a bypass pipeline and a quick cleaning interface

● Detachable filter construction is recommended

4.Safeguard measures for hydraulic characteristics

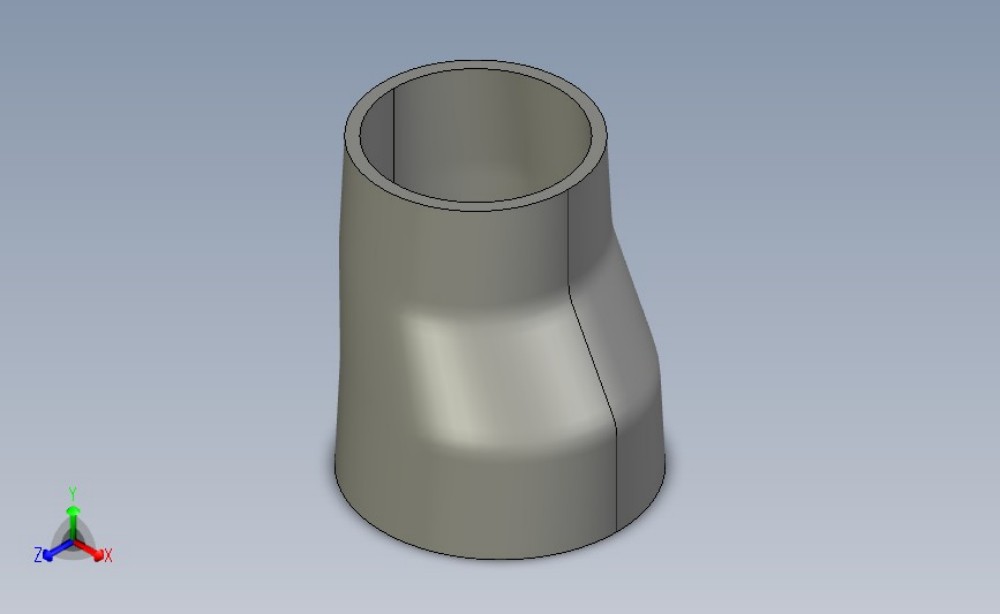

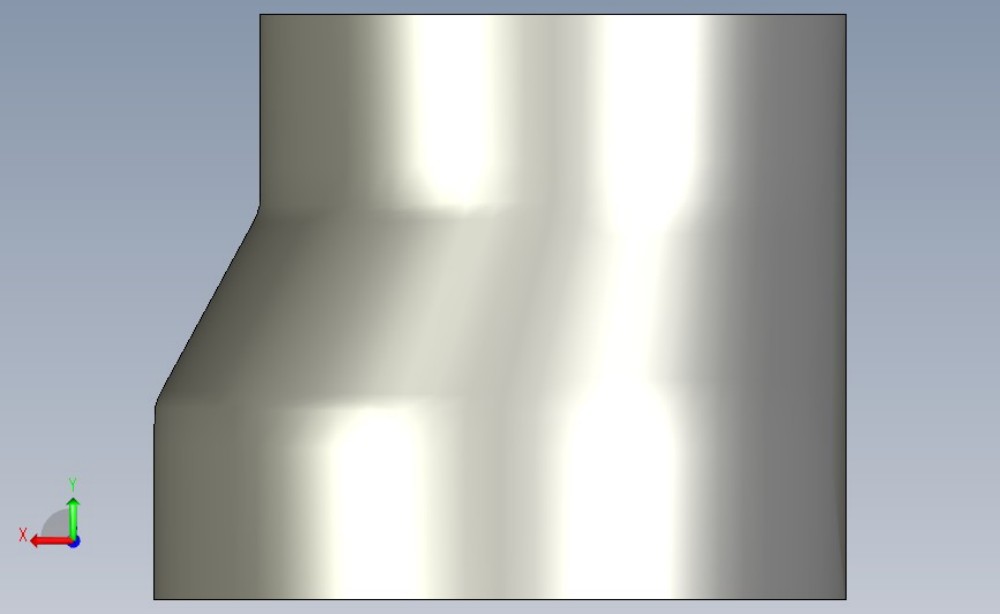

Eccentric reducer selection:

● Standard pressed reducers must be used (according to SH/T 3406)

● The angle of the reducer should be ≤8° to prevent sudden changes in local resistance

Flow Optimization:

● The length of the straight pipe section before and after the reducer should be ≥ 5 times the pipe diameter

● CFD simulations are recommended to verify the flow rate distribution

5.Precautions for project implementation

Stress test:

● The system pressure test should be 1.5 times the working pressure

● The holding time is not less than 2 hours

Flushing Protocol:

● Pickling passivation should be carried out before system installation

● The flushing flow rate should be ≥ 1.5m/s

Acceptance Criteria:

● The accuracy level of the pressure gauge should not be lower than 1.6

● The filter differential pressure should be ≤ 0.02MPa

6.This specification system has been included in the "Technical Specifications for Fire Water Supply and Fire Hydrant Systems" GB50974, and it is recommended to carry out HAZOP analysis in combination with specific projects, focusing on the following risk points:

● Risk of backflow of media due to failure of check valves

● Risk of water supply failure due to clogged filters

● Risk of overpressure operation due to pressure gauge failure

● Risk of hydraulic shock caused by improper installation of reducers

It is recommended to adopt a digital monitoring scheme, configure pressure sensors, flow monitors and vibration analyzers, and establish a smart fire pump room management system to achieve real-time status monitoring and fault warning.

Post time: Mar-24-2025