Proper pump motor installation is critical for ensuring optimal performance, energy efficiency, and long-term reliability. Whether for industrial, commercial, or municipal applications, adherence to installation specifications and selection of the appropriate structural form can prevent operational failures, excessive wear, and safety hazards.

The structure and installation type code of the pump motor shall comply with the provisions of GB997. The code name consists of the abbreviation "IM" for "International Mounting", the "B" for "horizontal mounting", the "V" for "vertical mounting" and 1 or 2 Arabic numerals. Such as IMB35 or IMV14, etc. The Arabic numerals after B or V represent different construction and installation features.

There are four categories of common installation types for small and medium-sized motors: B3, B35, B5 and V1

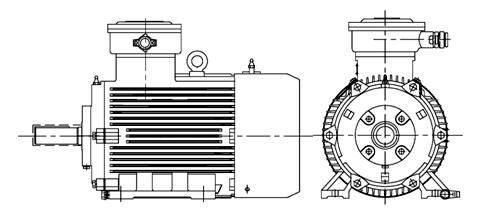

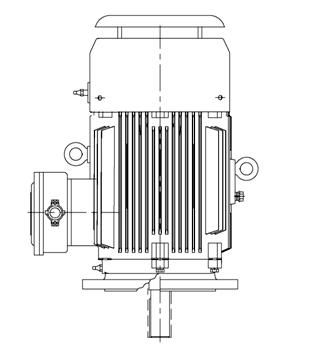

- 1.B3 installation method: the motor is installed by the foot, and the motor has a cylindrical shaft extension

The B3 installation method is one of the most common motor mounting configurations, where the motor is installed by its feet and features a cylindrical shaft extension. This standardized arrangement is widely used in industrial, commercial, and municipal pump systems due to its stability, ease of installation, and compatibility with various driven equipment.

According to IEC 60034-7 and ISO 14116, the B3 mounting refers to:

Foot-mounted motor (bolted to a baseplate or foundation).

Cylindrical shaft extension (smooth, cylindrical, and parallel keyway if required).

Horizontal orientation (shaft parallel to the ground).

Key Features

✔ Rigid base mounting for vibration resistance.

✔ Easy alignment with pumps, gearboxes, or other driven machinery.

✔ Standardized dimensions (IEC/NEMA flange compatibility).

The B3 installation method remains a reliable, standardized approach for mounting horizontal motors in pump systems. Proper foot mounting, shaft alignment, and foundation preparation are critical for optimal performance.

Need help selecting the right motor mounting configuration? Consult an engineer to ensure compliance with IEC/ISO/NEMA standards.

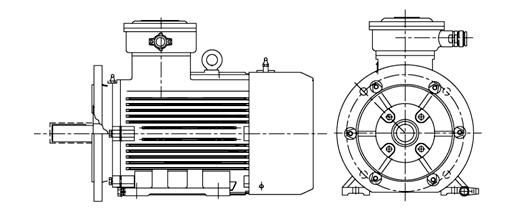

- 2. B35 installation method: motor with foot, shaft extension end with flange

The B35 installation method is defined by IEC 60034-7 and ISO 14116 as a combination mounting type featuring:

Foot mounting (baseplate installation)

Flanged shaft extension (typically to C-face or D-face standards)

Horizontal orientation (shaft parallel to mounting surface)

The B35 installation method offers superior stability and alignment precision for critical applications. Its dual mounting system provides the reliability of foot mounting with the accuracy of flange connection, making it ideal for medium-to-large motor installations where vibration control and maintenance access are paramount.

- 3.B5 installation method: the motor is installed by the flange of the shaft extension

The B5 installation method, as defined by IEC 60034-7 and NEMA MG-1, represents a flange-mounted motor configuration where:

The motor is solely supported by its shaft-end flange

No foot mounting provisions exist

The flange provides both mechanical support and precise alignment

This mounting type is particularly common in:

Compact pump applications

Gearbox connections

Space-constrained installations

The B5 installation method offers unparalleled compactness and precision for motor installations where space optimization and alignment accuracy are critical. Its flange-mounted design eliminates baseplate requirements while providing superior vibration characteristics.

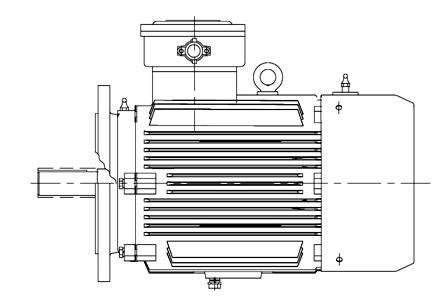

- 4.V1 installation method: the motor is installed by the flange of the shaft extension, and the shaft extension is facing down

The V1 installation method is a specialized vertical mounting configuration defined by IEC 60034-7 where:

The motor is flange-mounted (typically B5 or B14 style)

The shaft extension points vertically downward

The motor is suspended by its flange without foot support

This arrangement is particularly common in:

Vertical pump applications

Mixer installations

Limited-space industrial equipment

The V1 installation method provides an optimal solution for vertical applications requiring compact design and precise alignment. Its downward shaft orientation makes it particularly suitable for pump and mixer applications where gravity-assisted sealing is beneficial.

Post time: Mar-27-2025