Centrifugal pumps are among the most widely used mechanical devices for moving liquids in a variety of industries, from water treatment and agriculture to oil and gas and manufacturing. These pumps operate on a straightforward yet powerful principle: using centrifugal force to transport liquids efficiently and reliably. But how exactly do they work?

Understanding the Basics of Centrifugal Pumps

A centrifugal pump is a type of dynamic pump that uses the kinetic energy of a rotating impeller to increase the velocity of a fluid. This velocity is then converted into pressure energy, enabling the fluid to be transported through a piping system.

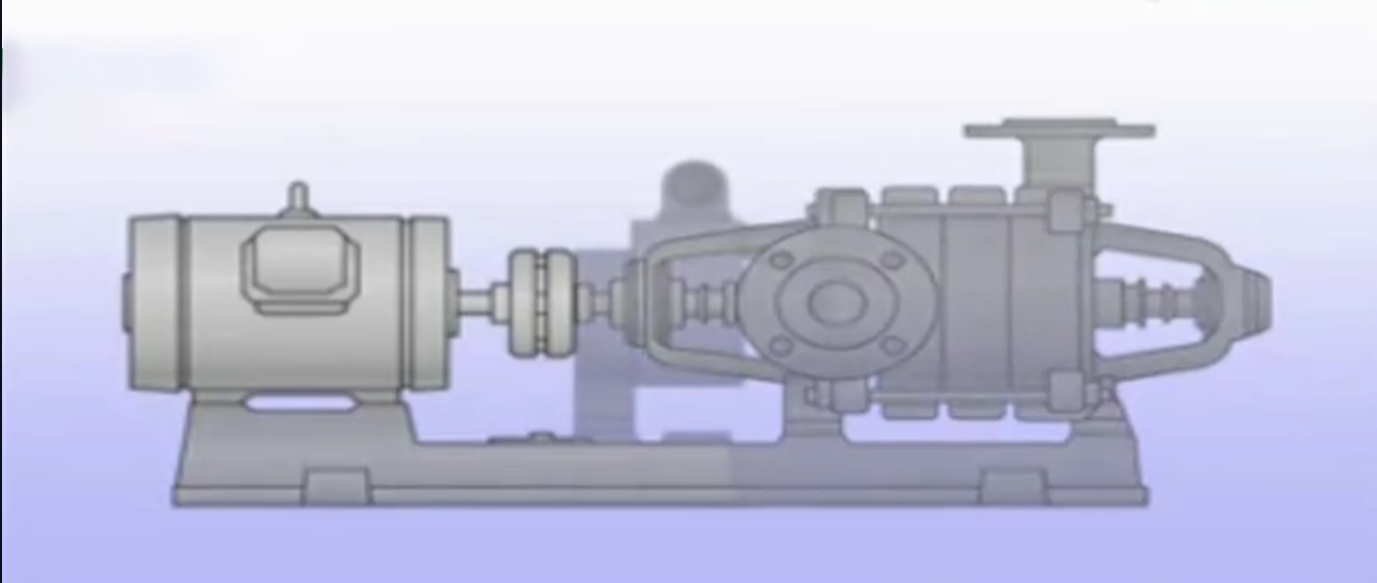

Centrifugal pumps play a huge role in the transfer of liquids. Centrifugal pump is composed of many parts, which can be roughly divided into three types according to the working state of each component during operation:

The impeller is the core component of the pump, which can make the water gain kinetic energy and produce flow.

The pump shaft is used to rotate the impeller.

The pump casing is composed of several parts, and its inner chamber forms the impeller chamber, the suction chamber and the pressurized chamber.

The Role of Centrifugal Force

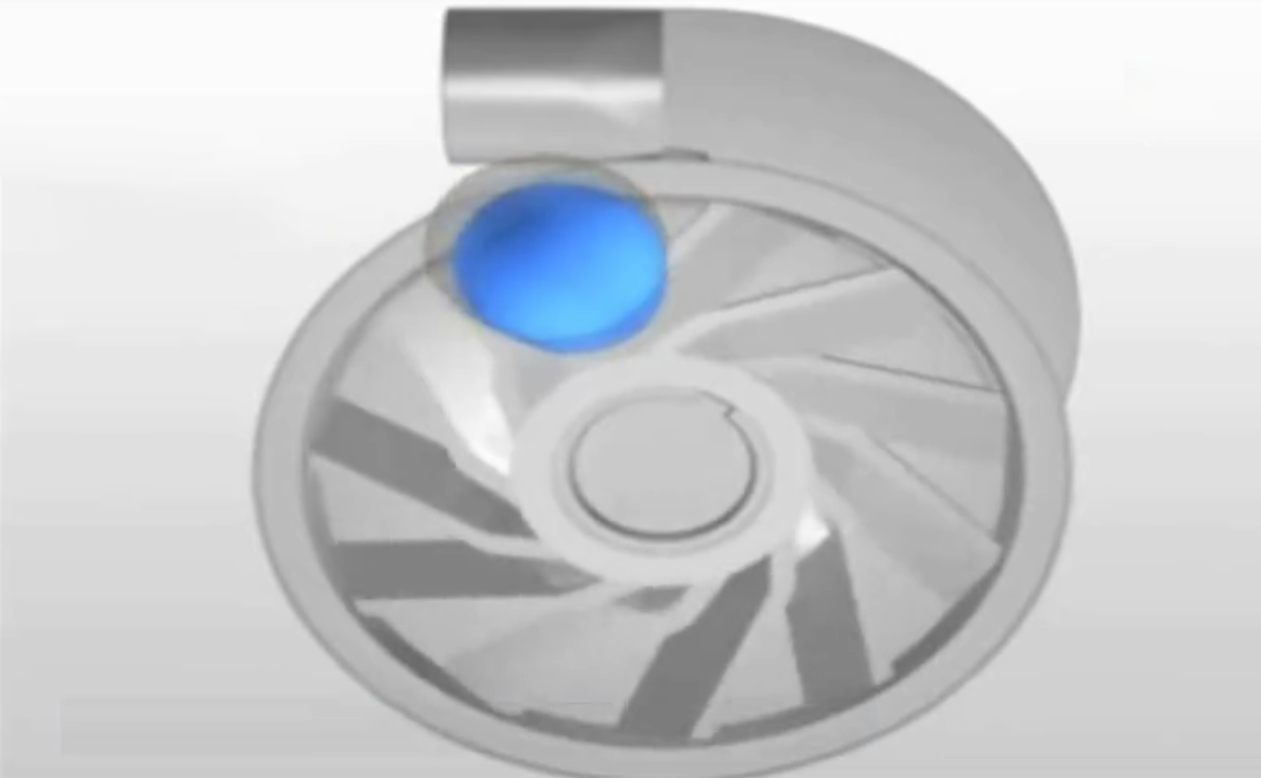

Centrifugal pumps work by using the centrifugal force generated by water generated by the rotation of the impeller. Before starting the centrifugal pump, the pump casing and suction chamber must be filled with water, and then the motor must be started to make the pump shaft drive the impeller and water to do high-speed rotary motion. Under the action of centrifugal force, the water is thrown to the outer edge of the impeller and flows into the pressurized water line of the pump through the flow channel of the snyl pump casing.

At the center of the impeller of the water pump, the water in the suction tank is pressed into the pump casing under the action of atmospheric pressure because the water is thrown out under the action of centrifugal force to form a vacuum. The impeller continuously rotates so that the water continues to flow in and out under the action of the impeller, which achieves the purpose of transporting water.

Here’s how the process unfolds:

Fluid Entry: Liquid enters the pump through the suction port and flows to the center of the impeller, known as the eye.

Energy Transfer: As the impeller spins (powered by a motor), it accelerates the fluid outward due to centrifugal force. This outward movement increases the fluid’s velocity.

Conversion to Pressure: When the high-velocity fluid leaves the impeller, it enters the pump casing, where its velocity is reduced. This drop in velocity causes the kinetic energy to be converted into pressure energy.

Fluid Discharge: The now pressurized liquid exits the pump through the discharge port, ready to be delivered through pipelines to its destination.

Efficiency and Applications

Centrifugal pumps are valued for their simplicity, durability, and efficiency. They are best suited for transporting low-viscosity liquids such as water, chemicals, and light oils. Because of their design, they can handle large volumes of liquid at relatively low pressure.

Common applications include:

Municipal water supply

Irrigation systems

Industrial fluid transfer

Cooling and heating systems

Firefighting

Conclusion

Centrifugal pumps effectively harness the power of centrifugal force to move fluids, transforming rotational energy into hydraulic energy with minimal mechanical complexity. Their ability to handle continuous flow, combined with ease of maintenance, makes them indispensable in both commercial and industrial operations.

Post time: Apr-21-2025