You rely on dewatering pumps to keep worksites safe and efficient. These pumps help manage water during construction, mining, and municipal projects. Removing unwanted water protects equipment, prevents accidents, and supports environmental safety.

- Today, dewatering pumps serve construction, mining, industrial, and municipal industries.

- The global market for dewatering solutions could reach USD 10.86 billion by 2030, with a 5.16% annual growth rate.

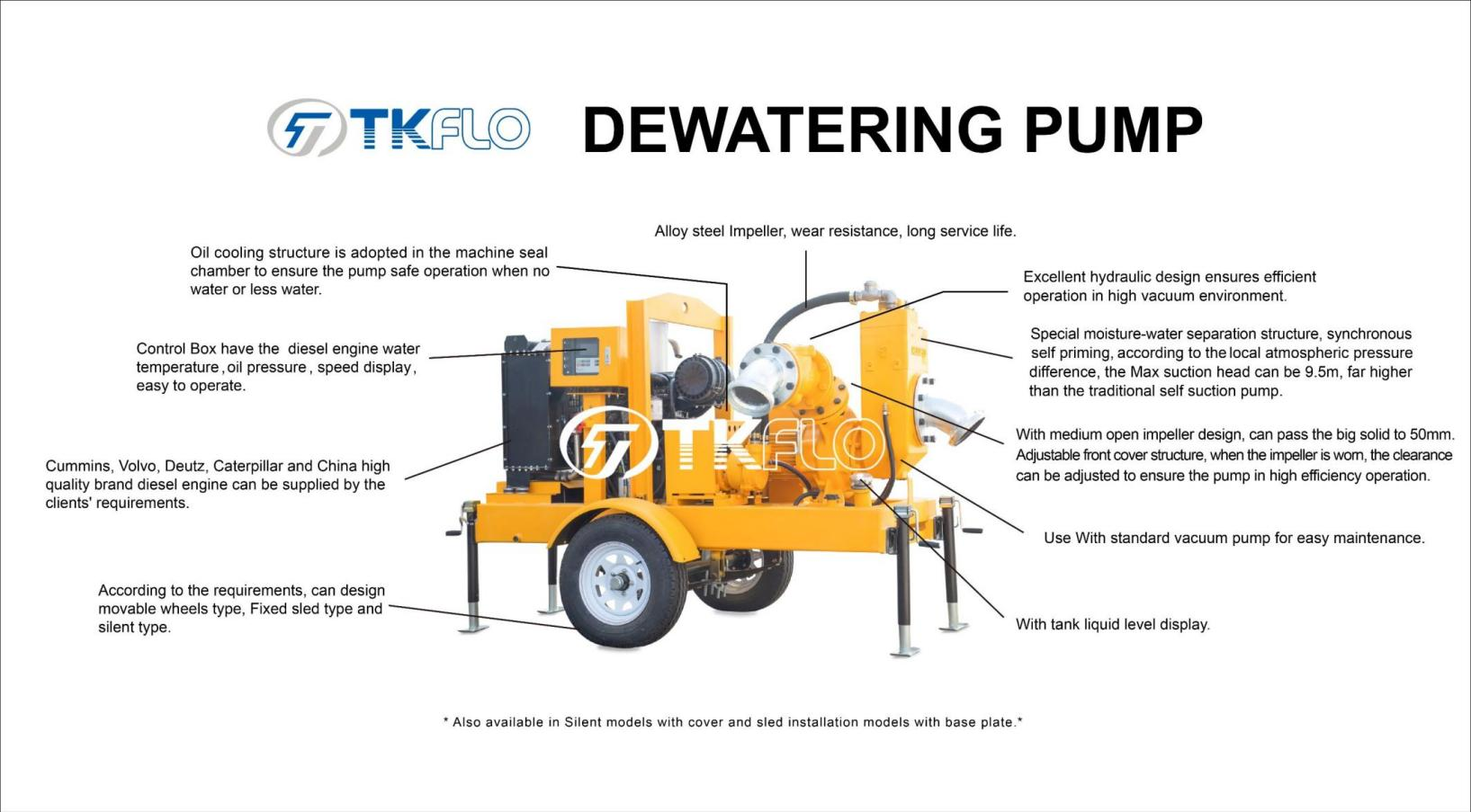

Selecting the right pump and keeping it in good condition ensures strong performance, whether you need to handle flood water or an emergency. Brands like TKFLO use advanced technology to deliver reliable and sustainablater management solutions.

Key Takeaways

- Dewatering pumps are essential for keeping worksites safe and efficient by removing unwanted water.

- Choosing the right type of dewatering pump, such as submersible or centrifugal, enhances safety and productivity on construction and mining sites.

- Regular maintenance, including cleaning and lubrication, extends the life of your dewatering pump and reduces repair costs.

- Dewatering pumps play a crucial role in agriculture by managing water levels, which can increase crop yields by 20-30%.

- Innovative brands like TKFLO offer advanced, energy-efficient pumps that help meet environmental standards and improve water management.

Dewatering Pump Types

You can find many types of dewatering pumps in different industries. Each type helps you move water away from your worksite. Choosing the right pump makes your job safer and more efficient.

Submersible Dewatering Pumps

Submersible dewatering pumps work underwater. You place these pumps in deep pits or flooded areas. The pump pushes water up to the surface. This type is perfect for removing water from basements, tunnels, or construction sites after heavy rain.

TKFLO offers advanced submersible pumps with features that set them apart. Their brushless doubly fed frequency conversion integrated motor helps you save energy. The efficient ternary flow impeller uses 3D printing and flow field diagnostic technology. These features give you better performance and lower power costs.

Centrifugal Dewatering Pumps

Centrifugal dewatering pumps use a spinning impeller to move water quickly. You can use these pumps for large drainage jobs. They work well when you need to remove a lot of water fast, such as on big construction sites or in mining operations.

TKFLO’s high-efficiency energy-saving pumps use advanced impeller designs. These pumps can improve energy efficiency by up to 40% compared to older models. You get strong water flow and reliable results.

Diaphragm Dewatering Pumps

Diaphragm dewatering pumps use a flexible membrane to move water. You can use these pumps for muddy or dirty water. They are great for smaller jobs where you need to control water flow carefully. These pumps work well in places with lots of debris or thick sludge.

Specialty Pumps

Some jobs need special types of dewatering pumps. Wellpoint pumps remove water from shallow areas using a network of pipes. Piston pumps use a piston to move water steadily. You might use these pumps for groundwater control or when you need a steady flow.

Tip: Always match the pump type to your site’s needs. TKFLO’s product range includes vertical turbine pumps, which are ideal for deep wells and fire protection systems. Their pumps combine technology and sustainability, helping you manage water efficiently.

Here is a quick overview of the main types of dewatering pumps and their functions:

| Pump Type | How It Works | Best Use Case |

|---|---|---|

| Submersible | Operates underwater, pushes water to surface | Deep pits, flooded areas |

| Centrifugal | Spinning impeller moves water rapidly | Large volume drainage |

| Diaphragm | Flexible membrane handles muddy water | Small, precise jobs |

| Wellpoint | Pipe network extracts shallow groundwater | Soft soil, groundwater control |

| Piston | Piston motion provides steady water movement | Consistent flow tasks |

You can see that the types of dewatering pumps offer solutions for many situations. TKFLO’s pumps give you advanced features and reliable performance for every job.

Dewatering Applications

Construction Sites

You see dewatering pumps on almost every construction site. These pumps help you remove unwanted water from excavations, tunnels, and foundations. Water can slow down your work and damage equipment. Dewatering keeps your site dry and safe.

- Water contamination often causes problems. You need to remove suspended solids to keep your site clean.

- Choosing the right pump helps you handle abrasion from dirty water.

- As you dig deeper, you need pumps with higher performance.

Dewatering pumps create a stable work environment. You can continue building without worrying about water entering your workspace. These pumps protect the soil and structure by stopping erosion and lowering hydrostatic pressure. You save money because heavy machines and workers can move freely.

TKFLO’s submersible and vertical turbine pumps give you reliable water management solutions. You can trust their pumps to handle emergency water management and keep your project on track.

Mining and Quarrying

Mining and quarrying industries face tough water challenges. You need to remove water from deep pits and manage muddy site water. Dewatering pumps help you keep your site safe and productive.

| Feature | Benefit |

|---|---|

| Movable Dry Self-Priming Pump | Efficiently removes water in challenging environments, crucial for mining and quarrying. |

| Handles muddy site water | Designed to manage water with suspended solids, common in mining operations. |

| Eliminates priming hassles | Allows for continuous operation, enhancing productivity without delays. |

| Built for durability | Engineered to withstand the rigors of mining and construction, reducing repair needs. |

| Diesel & Electric options | Provides flexibility for various operational requirements in remote or urban sites. |

TKFLO’s pumps work well in mining and quarrying applications. You can rely on their durable designs for emergency water management and long-term efficiency.

Agriculture and Irrigation

You use dewatering pumps in agriculture to control water levels and improve crop growth. These pumps help you deliver water directly to the root zone, increasing crop yields by 20-30%. You can manage excess water and keep soil moisture at the right level.

- Water pumps are essential for irrigation systems. You can give crops the right amount of water.

- Dewatering pumps help you remove extra water, keeping soil healthy.

- These pumps prevent waterlogging and support water conservation.

Dewatering pumps also help you use water efficiently. You can avoid wasting water and protect your crops from damage. TKFLO’s energy-saving pumps support precision irrigation and sustainable farming practices.

Oil, Gas, and Industry

You find dewatering pumps in oil, gas, and industrial projects. These pumps help you manage water during drilling, production, and wastewater management. You need reliable pumps to keep your operations running smoothly.

| Feature/Benefit | Description |

|---|---|

| Self-Priming Technology | Eliminates manual priming, reducing downtime and maintenance costs. |

| Robust Construction | Ensures durability in challenging environments, enhancing reliability. |

| High Flow Capacity | Capable of handling substantial volumes of water efficiently, crucial for operational success. |

| Increased Productivity | Reduced downtime leads to faster project completion and enhanced operational efficiency. |

| Reduced Labor Costs | Less manual intervention required, leading to cost savings. |

| Improved Reliability | Minimizes the risk of priming errors, enhancing the dependability of the dewatering system. |

| Versatility | Adaptable to a wide range of dewatering applications across various industries. |

You must follow environmental regulations like the Clean Water Act and Safe Drinking Water Act. Dewatering pumps help you meet these standards and protect the environment. TKFLO’s pumps offer high flow capacity and robust construction for industrial projects.

Municipal and Environmental Projects

Municipal and environmental projects rely on dewatering pumps for flood control, stormwater management, and wastewater management. You need these pumps to respond to natural disasters and water-related emergencies.

The demand for dewatering pumps grows as extreme weather events become more common. You use these pumps to remove water from flooded areas and protect homes and infrastructure. Wastewater treatment plants depend on dewatering pumps to manage sewage and sludge.

| Role of Dewatering Pumps | Description |

|---|---|

| Stormwater Management | Helps manage stormwater to prevent urban flooding. |

| Wastewater Treatment | Ensures effective treatment of sewage and drainage systems. |

| Environmental Remediation | Aids in containing and remediating environmental hazards, improving soil and water quality. |

- Dewatering pumps manage stormwater and prevent urban flooding.

- You use these pumps for effective wastewater treatment.

- Dewatering helps you contain and clean up environmental hazards.

TKFLO’s pumps support emergency water management and environmental protection. You can trust their solutions for municipal and environmental applications.

Tip: Dewatering pumps play a key role in protecting communities from flood and water-related emergencies. You can improve safety, efficiency, and sustainability by choosing the right pump for your project.

Choosing a Dewatering Pump

Assessing Water and Site Conditions

You need to look at your site before you select a dewatering pump. Start by checking the type of water you must remove. Is it clean, dirty, or full of sludge? You should also measure how much water is present and how fast it flows into your work area.

- Scope of the dewatering task

- Type of water

- Flow rate

- Suction lift

- Discharge distance

- Pump size

- Solid processing capability

- pH resistance

You can identify the water type, check for solids, and figure out the pump’s needed capacity and discharge head. TKFLO listens to your needs and offers custom water management solutions for different industries.

Efficiency and Power Needs

You want a pump that works well and saves energy. Different pumps use power in different ways. Look at the table below to compare pump types:

| Pump Type | Advantages | Typical Applications | Power Use Characteristics |

|---|---|---|---|

| Centrifugal Pump | High flow rates, simple design | Construction, agriculture | Efficient for low to medium head; power use rises with flow and pressure |

| Positive Displacement | Consistent flow, handles thick fluids | Oil, gas, food processing | Stable power use; higher for thick fluids |

| Submersible Pump | Compact, works underwater | Drainage, sewage, dewatering | Energy-efficient for submerged jobs; power use depends on depth and volume |

TKFLO’s pumps focus on efficiency and help you lower operational costs. You can choose the right pump for your site and save energy.

Environmental and Sustainability Factors

You should think about the environment when you choose a dewatering pump.

- Conduct site assessments to pick the best dewatering method

- Monitor groundwater quality to meet regulations

- Use filtration systems to treat discharged water

- Pick eco-friendly technologies, like solar-powered pumps

- Follow rules such as the Clean Water Act

- Use energy-efficient equipment

- Reuse water with sedimentation tanks

TKFLO supports sustainability by offering pumps that meet energy standards and help protect local ecosystems.

Tip: Choose contractors who care about sustainability and use equipment that saves energy.

Real-World Selection Examples

You can match pump types to your industry needs. See the table below for examples:

| Pump Type | Application Description | Industry Use Case |

|---|---|---|

| Submersible Pump | Removes water from pools and basements quickly | Heavy-duty applications |

| Centrifugal Pump | Moves water fast with a spinning impeller | Construction, agriculture |

| Utility Pump | Handles small drainage tasks in homes | Minor flooding, small pools |

| Trash Pump | Works with water mixed with debris outdoors | Outdoor drainage, muddy areas |

TKFLO’s customer-centric approach means you get pumps tailored to your site and project. You can trust their service network to support your dewatering needs in industrial and other industries.

Dewatering Pump Maintenance

Routine Checks

You keep your dewatering pump working well by following a regular maintenance routine. Start by cleaning the pump with fresh water. Use a soft brush to remove dirt from the intake and discharge ports. Lubricate all moving parts with high-quality lubricants and check the levels often. This reduces wear and keeps the pump running smoothly.

Check your pump each season. In spring, look for any damage. In summer, make sure the pump works efficiently. Before winter, drain all water and protect the pump from freezing. These steps help you avoid problems and keep your water management solutions reliable.

Tip: A clean and well-lubricated pump improves efficiency and helps you manage water and wastewater with less trouble.

Troubleshooting

Sometimes, your pump may not work as expected. You can use this table to find common issues and solutions:

| Issue | Possible Causes | Solutions |

|---|---|---|

| Pump Not Starting | Power supply issues, motor problems, loose connections | Check power, inspect motor, secure connections |

| Pump Running but Not Pumping | Clogged inlet/outlet, air leaks, worn impeller | Clean inlet/outlet, check for leaks, replace impeller |

| Low Pump Performance | Clogged filters, wrong pump size, high head height | Clean filters, check pump size, adjust head height |

| Overheating Pump | Not enough water, blocked cooling, long running time | Ensure water supply, clean cooling, allow pump to cool |

| Unusual Noises | Air leaks, loose parts, worn bearings | Check for leaks, tighten parts, replace bearings |

You solve most problems by cleaning, checking connections, and replacing worn parts. This keeps your pump ready for water and wastewater management tasks.

Extending Service Life

You extend the life of your dewatering pump by staying proactive. Regular maintenance helps you spot small issues before they become big problems. Routine inspections let you fix things early, which prevents breakdowns. Preventive care means your pump lasts longer and you spend less on repairs.

TKFLO pumps have a strong reputation for durability. The company holds certifications like ISO 9001-2015 and ISO 14001. Customers trust TKFLO because their pumps have performed well for over ten years. Many users praise the reliability and efficiency of these pumps in handling water and wastewater.

When you take care of your pump, you get better efficiency and fewer interruptions. This helps you manage water, wastewater, and even wastewater management projects with confidence.

Dewatering pumps help you keep construction sites dry, protect mining tunnels, support agriculture, and manage water in cities.

- You improve safety and efficiency by choosing the right pump for your job.

- Regular maintenance extends your pump’s life and saves money.

- The market for dewatering pumps keeps growing as new technology and automation make water management easier.

Consider innovative brands like TKFLO. Their sustainable solutions use smart technology to help you meet environmental goals and stay ahead in your industry.

FAQ

What is a dewatering pump?

A dewatering pump helps you remove unwanted water from a worksite. You use it to keep areas dry and safe. These pumps work in construction, mining, agriculture, and municipal projects.

How do you choose the right dewatering pump?

You check your site conditions, water type, and flow rate. You match the pump to your needs. TKFLO offers solutions for deep wells, dirty water, and emergency drainage.

How often should you maintain your dewatering pump?

You should inspect your pump every season. Clean the intake and discharge ports. Lubricate moving parts. Regular checks help you avoid breakdowns and keep your pump working efficiently.

Can dewatering pumps handle dirty or muddy water?

Yes, you can use diaphragm and trash pumps for dirty or muddy water. TKFLO’s pumps handle water with solids and debris. You keep your site clean and safe with the right pump.

What makes TKFLO pumps different?

TKFLO combines advanced technology with energy-saving designs. You get reliable performance and strong durability. Customers trust TKFLO for efficient solutions and excellent support.

Post time: Jun-23-2025